Servo Press Systems

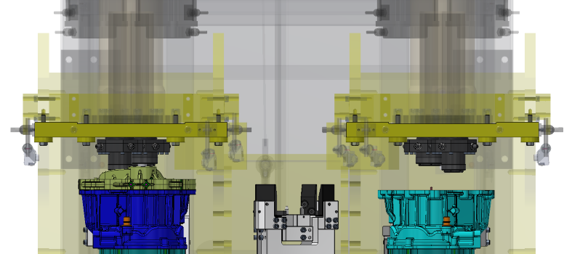

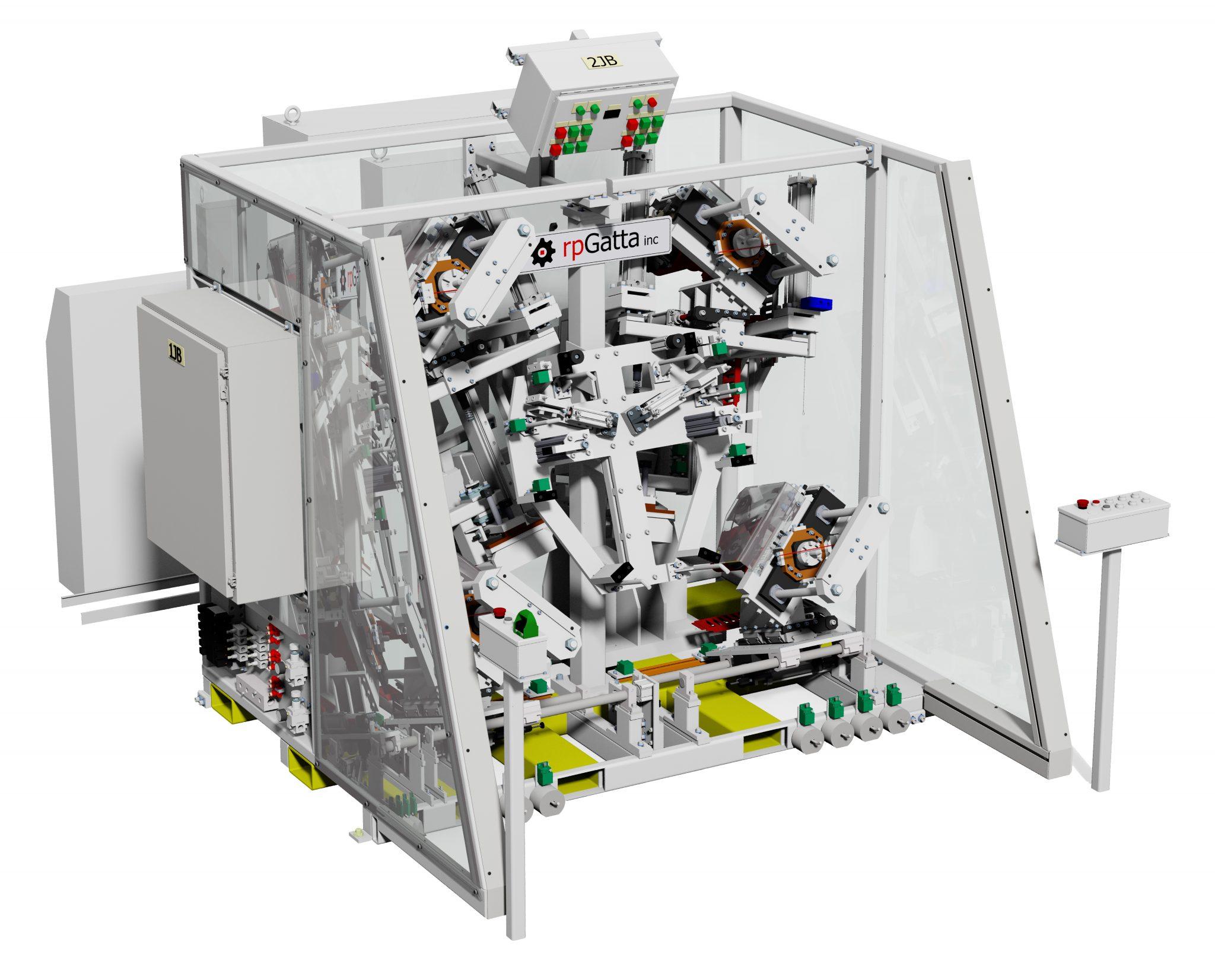

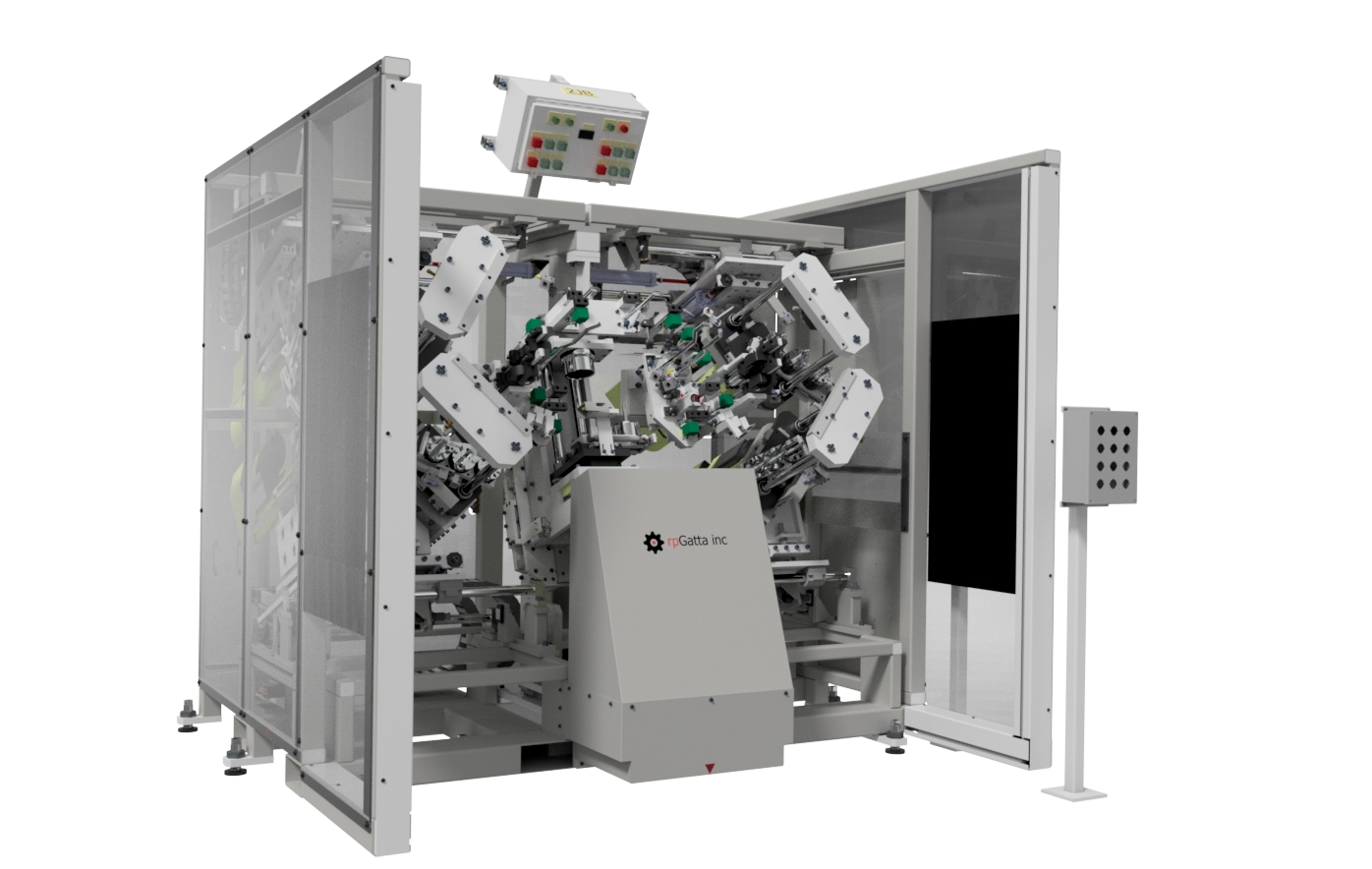

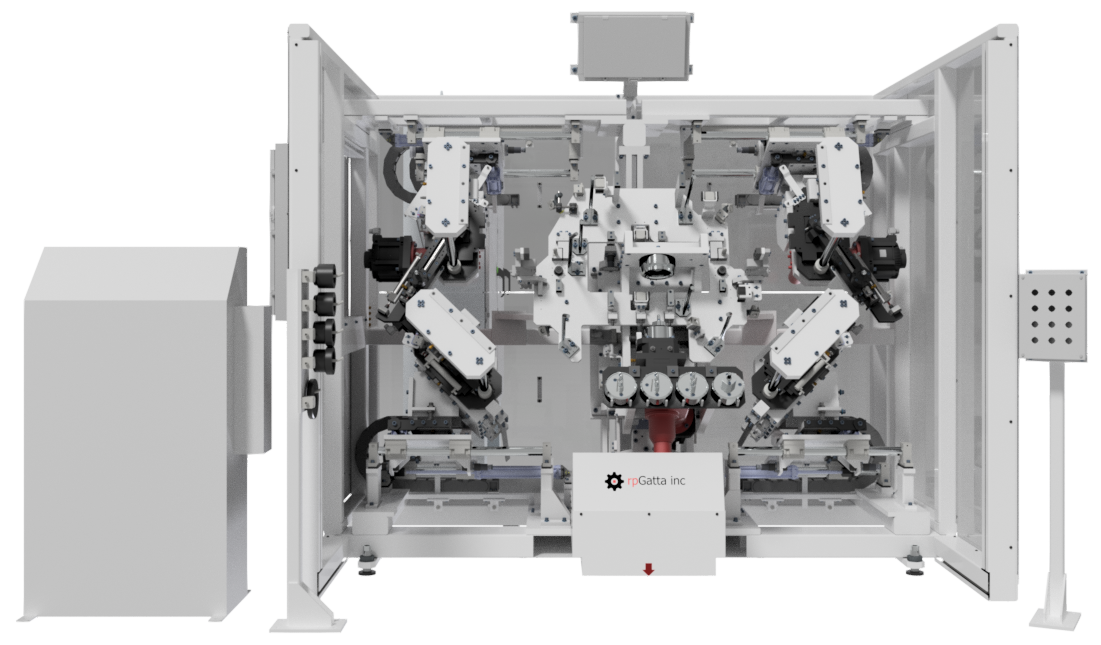

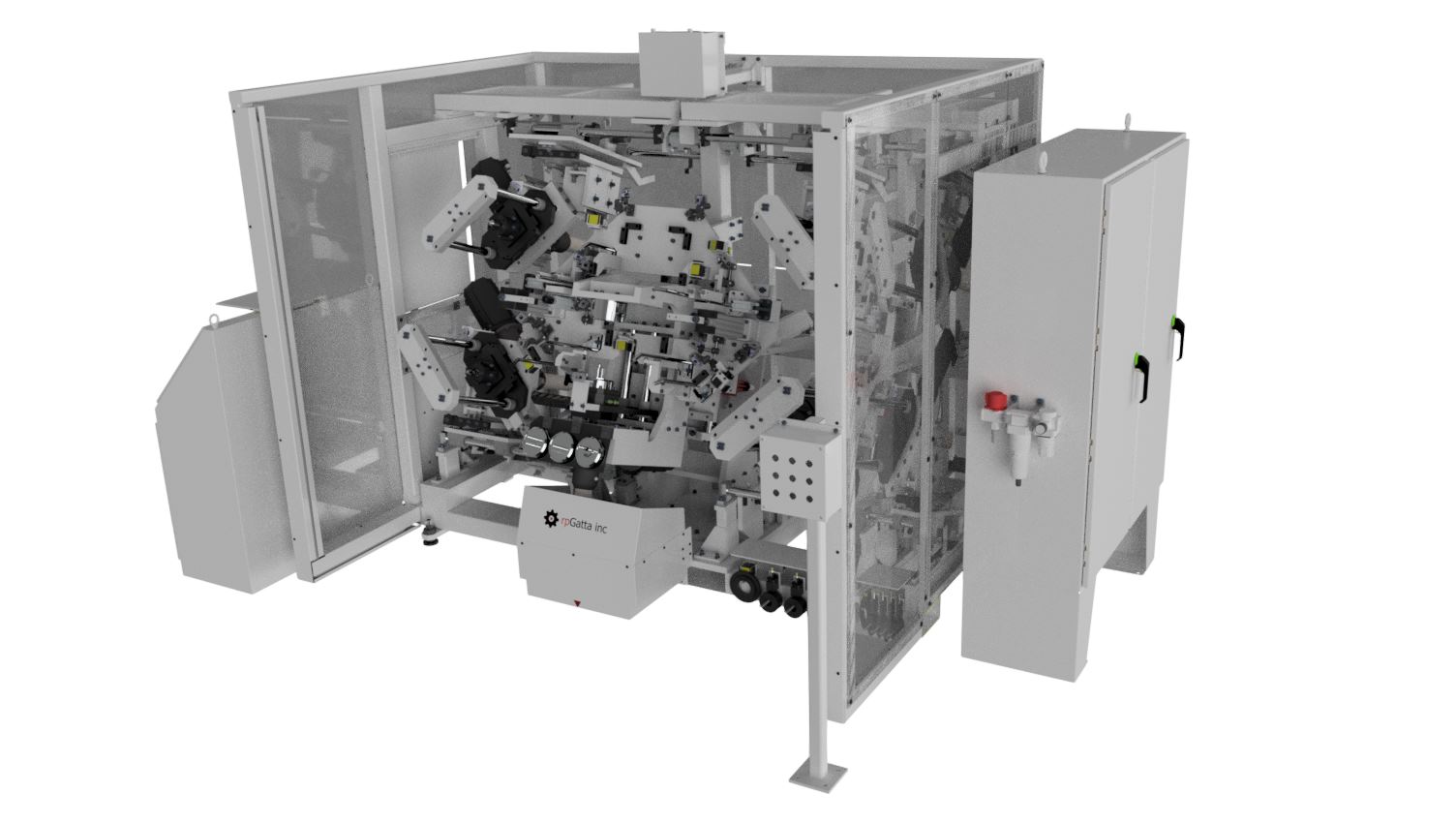

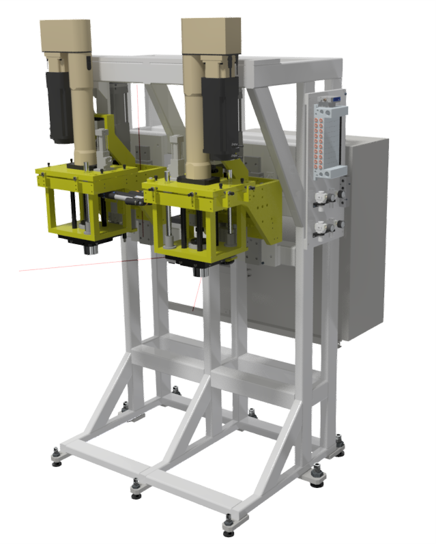

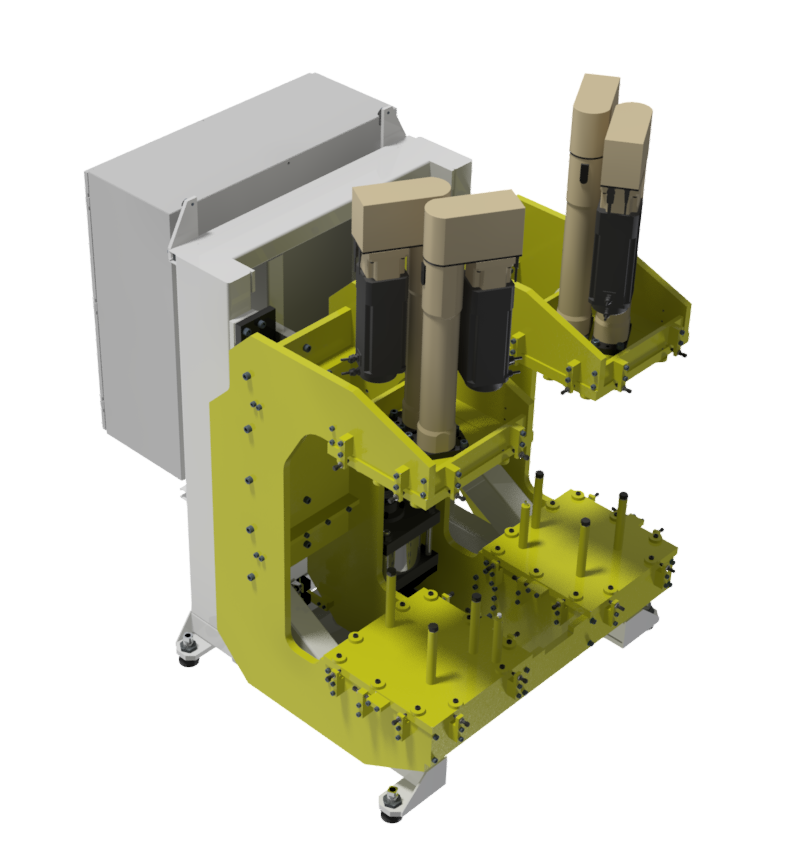

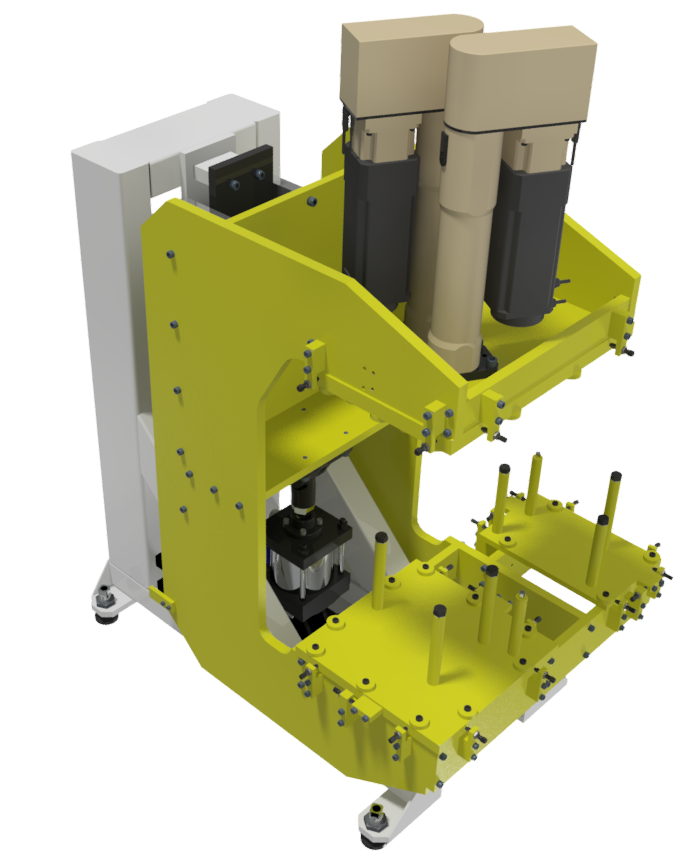

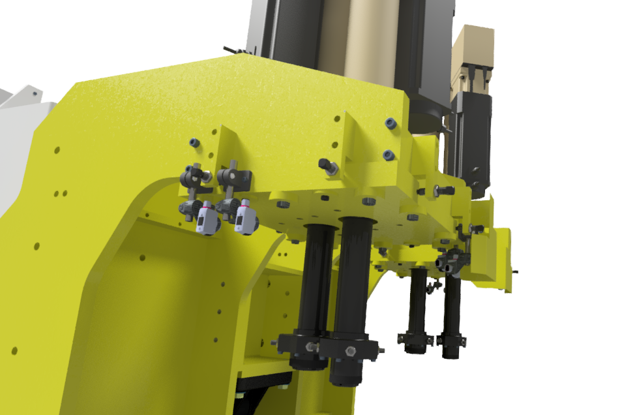

Bushing Press Systems

rpGatta’s high reliability bushing presses are custom designed to quickly and accurately press bushings into sub frames:

- Flexible system is capable of handling multiple frame and bushing variations

- Multiple servo press assemblies utilize force and distance monitoring to ensure reliable placement

- Orienting the frame at a slight angle allows one operator to ergonomically load the frame and bushings

- Error proof bushing placements ensures that the operator places the correct bushing in the correct orientation

- PLC controls, Operator HMI, and light curtains ensure maximum safety and equipment up time

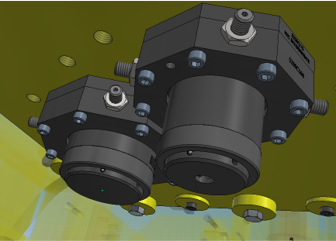

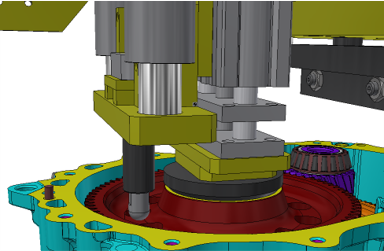

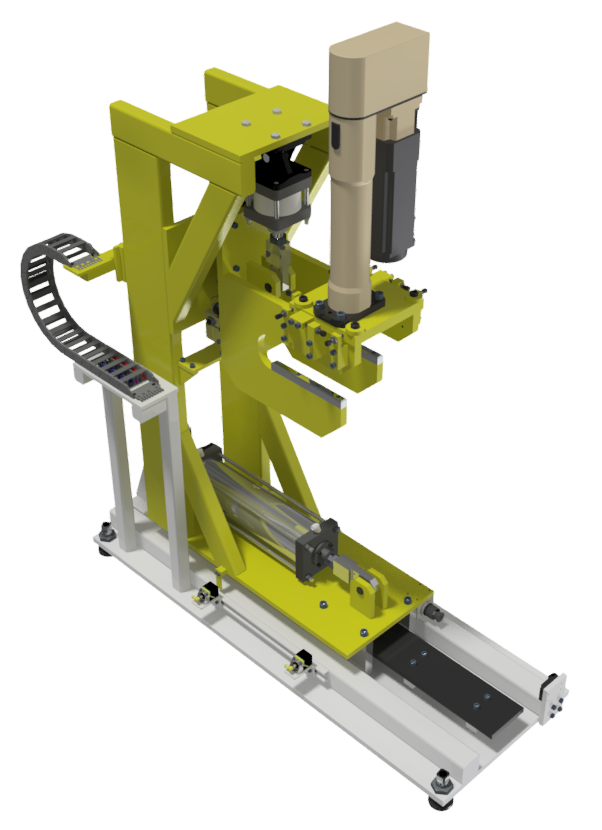

Pinion Press

Features:

- Utilizes 2 FEC servo presses to press fit each pinion gear on two A-Shield motor shafts

- Full press reaction force is contained within the equipment by attaching to the A-Shield motor shaft tapped hole with custom spindle

- +/- 2mm of X-Y float designed into press tooling to account for pallet and part variance

- Equipment bottoms out on top surface of motor shaft to set datum for accurate press distance data

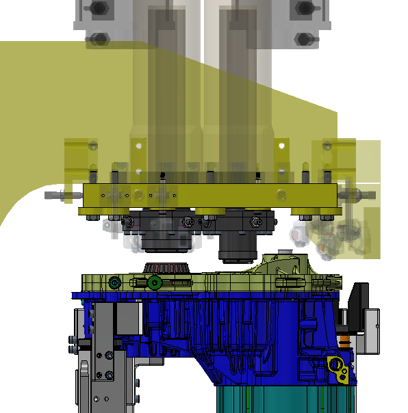

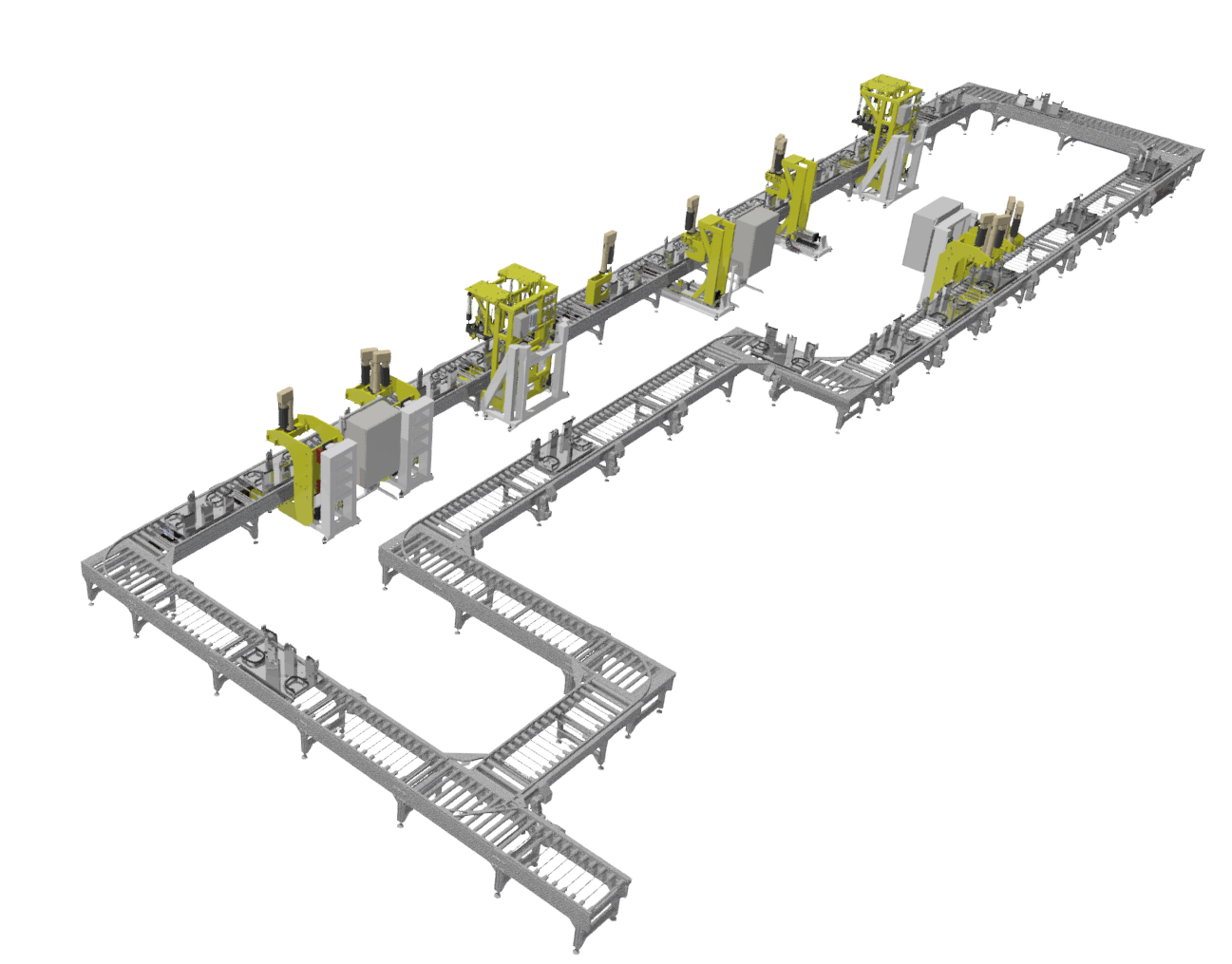

Gearbox Assembly Line Presses

Features:

- The conveyor transfers pallets from station to station

- Manual stations in between press stations where operators can load parts

- Each of the (8) custom servo presses installs a different part

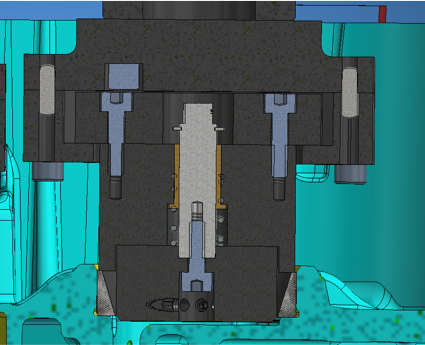

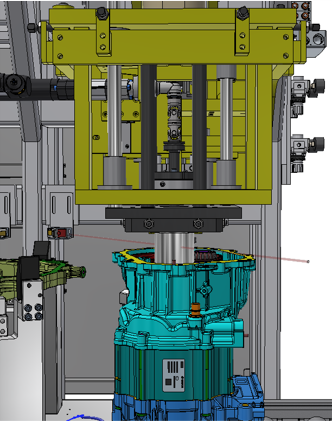

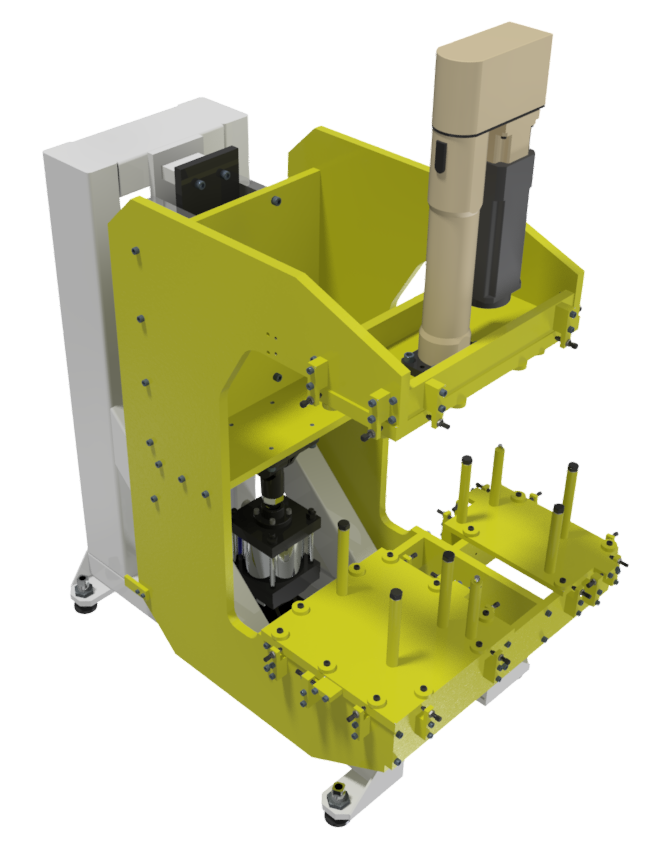

Floating Press Tooling

Features:

- Press tooling designed to retain intermediate and output outer races onto pilot

- +/- 2mm of X-Y float designed into press tooling to account for pallet and part variance

- Intermediate press tooling bottoms out on press surface and compresses to avoid interference

- Sensors added to ensure TRB’s are fully seated on press tooling

- Guarding added around front sensors to prevent operator interference

- Compressive tooling piloted by an oil embedded (self-lubricating) flanged bronze bushing and hardened shaft

- At full press the compressive tooling pilot will retract allowing tooling to not interfere when pressing the bearing into the C’Bore

- Once the ram starts to retract a spring will force the pilot back to its starting position

- The parts are offset so pilot will compress and bottom out on pressing ram before over compressing the spring