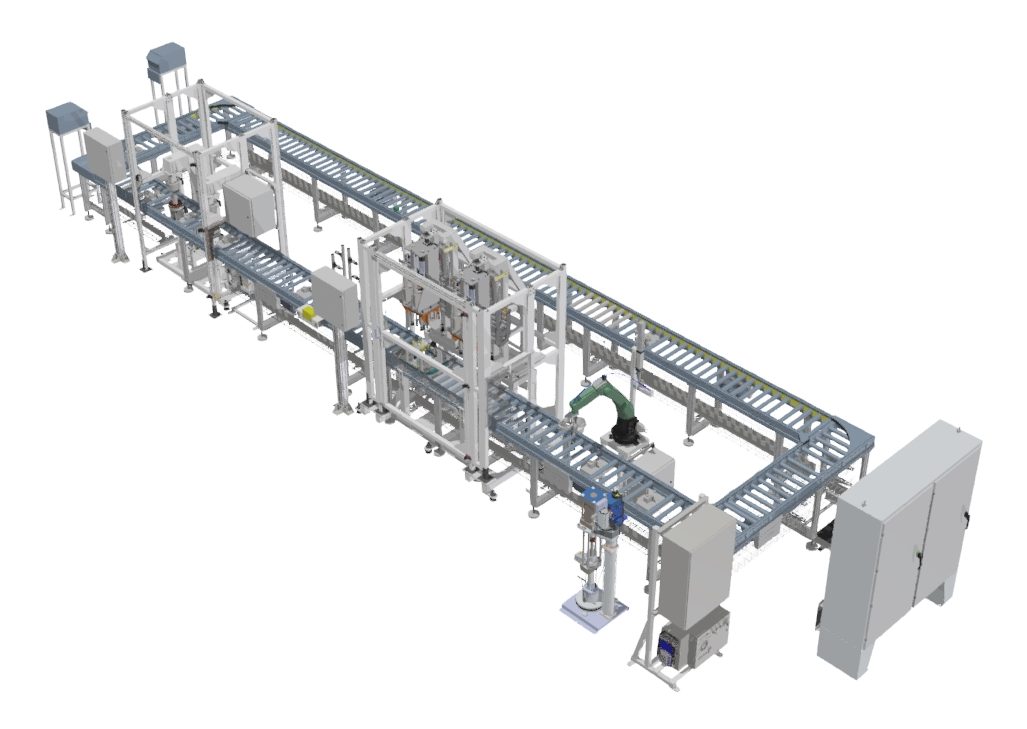

Conveyor Systems

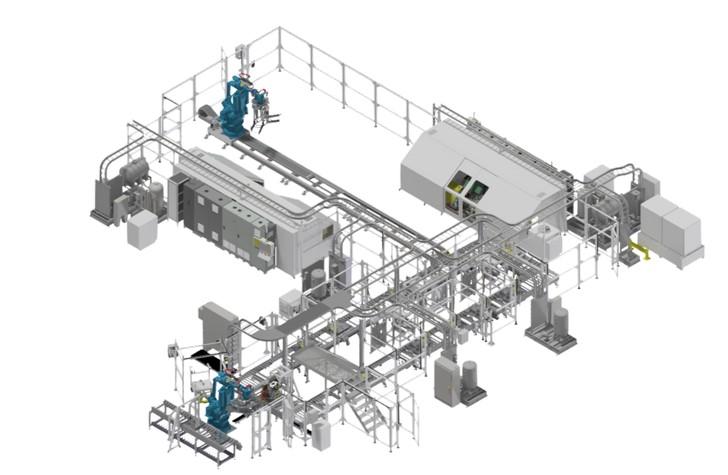

Corner Module Assembly System

Features:

- This loop conveyor assembles automotive car knuckle assemblies

- Station 1: Operator unloads the finished assemblies and installs them to the frame on the line then loads new knuckle bodies, rotors, and bearing hubs onto RH and LH pallets

- Vision confirms that the knuckles were loaded properly

- Barcode reader scans the printed out barcode associated with each knuckle

- Station 2: Automatic rotor runout for both RH and LH knuckles

- Station 3: Operator loads dust shield and calipers onto the knuckle assembly and hand starts the bolts

- Station 4: Vision and lasers error-proof the correct parts were loaded onto the assemblies

- Station 5: Dual multi-spindle assemblies lower onto the RH and LH assemblies to simultaneously torque six bolts at a time

- Station 6: Collaborative robot applies a ring of grease to the hub bearing and uses vision to error-proof the dispensing bead

- Station 7: Buffer for 16 completed RH and LH assemblies

- Station 1: Operator unloads the finished assemblies and installs them to the frame on the line then loads new knuckle bodies, rotors, and bearing hubs onto RH and LH pallets

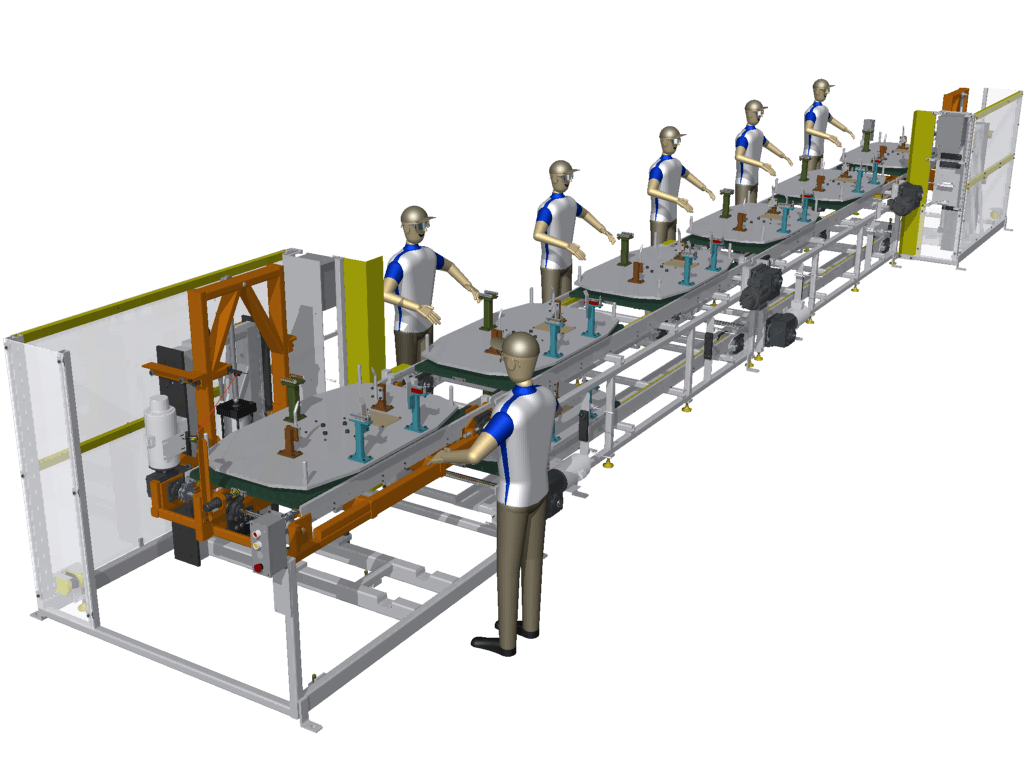

Front Suspension Pallet Conveyor

Features:

- Six Operator Stations

- Over-under recirculating conveyor

- Custom pallet bases and details to fixture the assemblies

- Independently controlled automated stops to be released by a work complete button

- Access from above to load/unload parts

Engine Cylinder Head Assembly Line

Features:

- 63 feet long recirculating pallet conveyor with elevators on each end

- Utilizes a total of five Fanuc robots

- Multiple manual and automated assembly stations

- Accommodates three different models of engine cylinder heads with the flexibility to accommodate additional future models

- Utilizes three bowl feeders for orienting and accumulating different size springs for each model

- Utilizes two bowl feeders for orienting and accumulating small keepers

- Utilizes two custom cam-designed cylinder head spring exercisers for testing and quality assurance

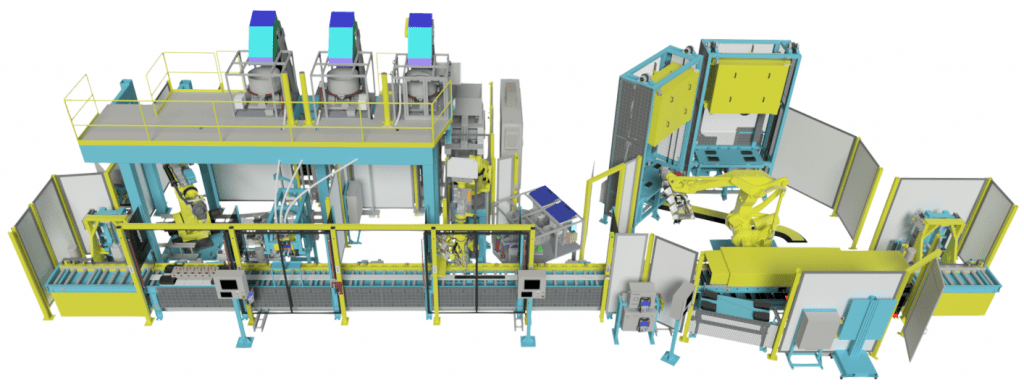

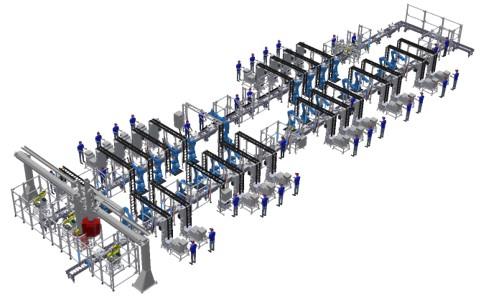

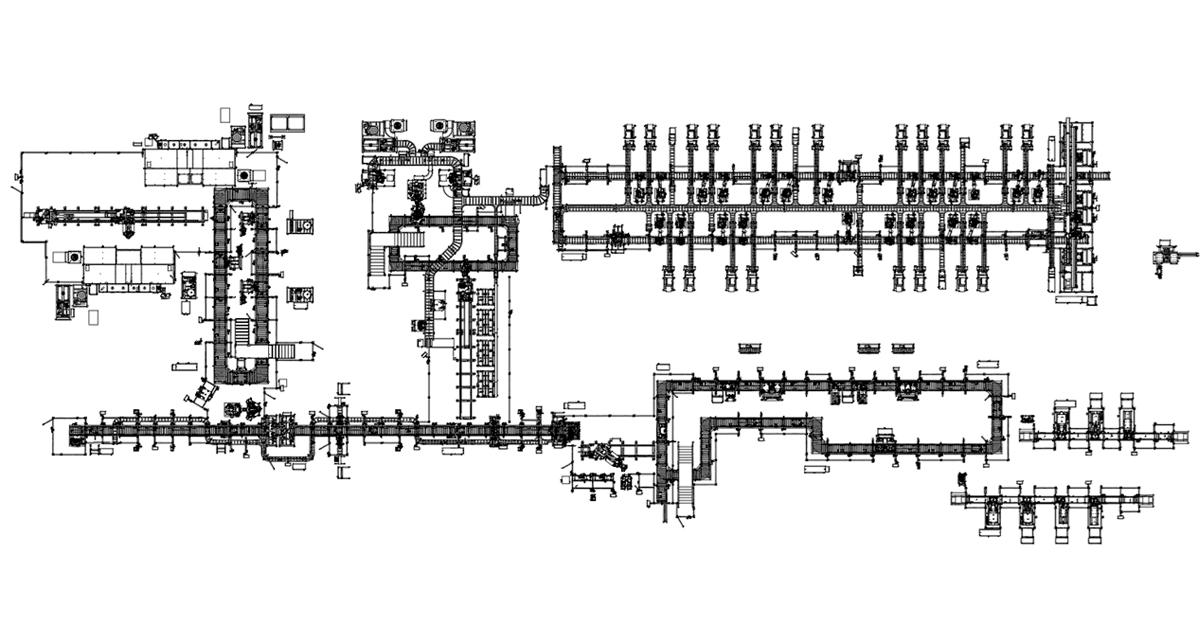

Drive Unit and Inverter Assembly Lines

Inverter Assembly Line Features:

- (20) Fastening Robots

- (2) Robotic Inspection Stations

- (4) Robotic Soldering Stations w/ AOI Inspection

- (1) Material Handling Gantry

- (2) End of Line Testing Material Handling Robots

- (2) Rejection Spurs

- (42) Automatic and Manual Work Stations

- Each conveyor is individually motorized and contains RFID readers and lift & locate systems for pallet positioning

- Each Pallet contains RFID tags and bushings for accurate locating

- ESD rated conveyor, pallets, and process

Drive Unit Assembly Line Features:

- 115 Total Stations

- 3 Robots

- 2 Assists

- 101 Total Conveyor Stations

- Each conveyor is individually motorized and contains RFID readers

- Lift & Locate systems for pallet positioning in auto stations

- Each pallet contains RFID tags and bushings for accurate locating

- 50% of buffer stations are populated with pallets for optimal buffering

- Station Quantities:

- M01 Gear Assembly: 14 Stations & 1 Assist

- M02 Gear Assembly Line: 12 Stations & 1 Assist

- Shield Assembly: 34 Stations

- Shield Marriage: 3 Stations & 1 Robot

- Assembly Conveyor: 29 Stations

- End of Line Cell: 20 Stations & 2 Robots