About Us

A Leading Automation Integrator Led by Engineers

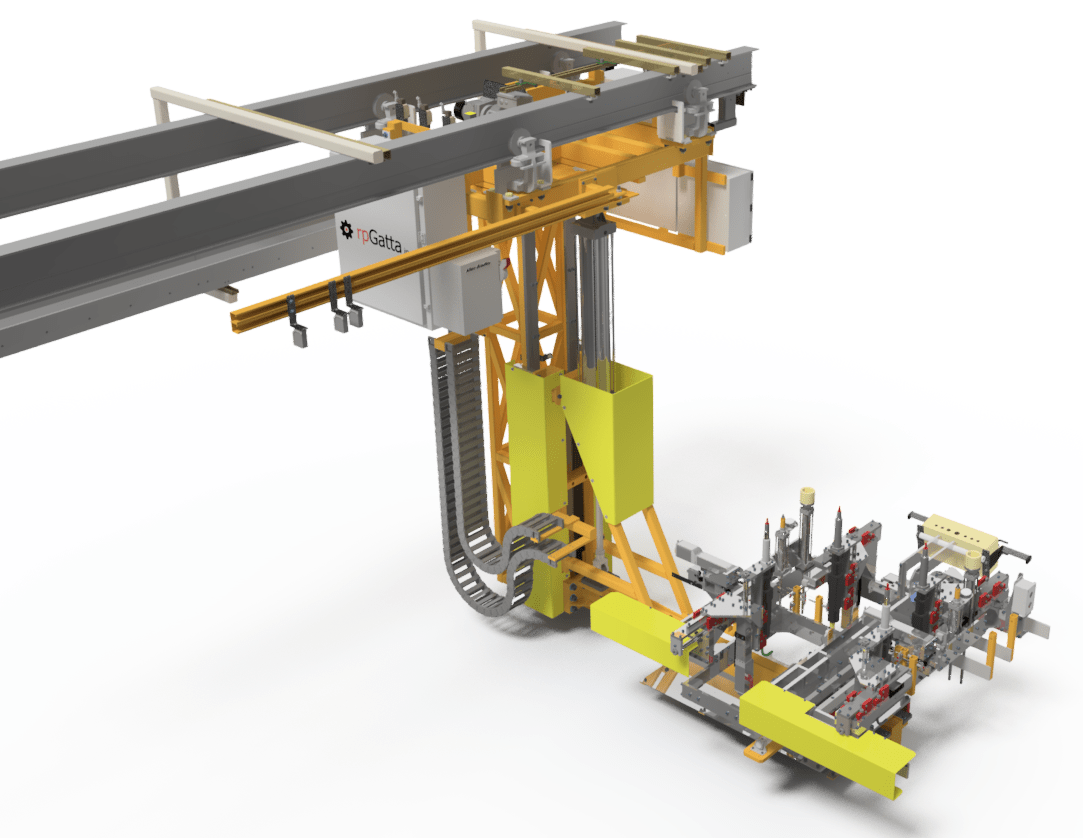

rpGatta, inc. is an innovative engineering firm with decades of experience in custom designing equipment to suit our customer’s specific manufacturing needs.

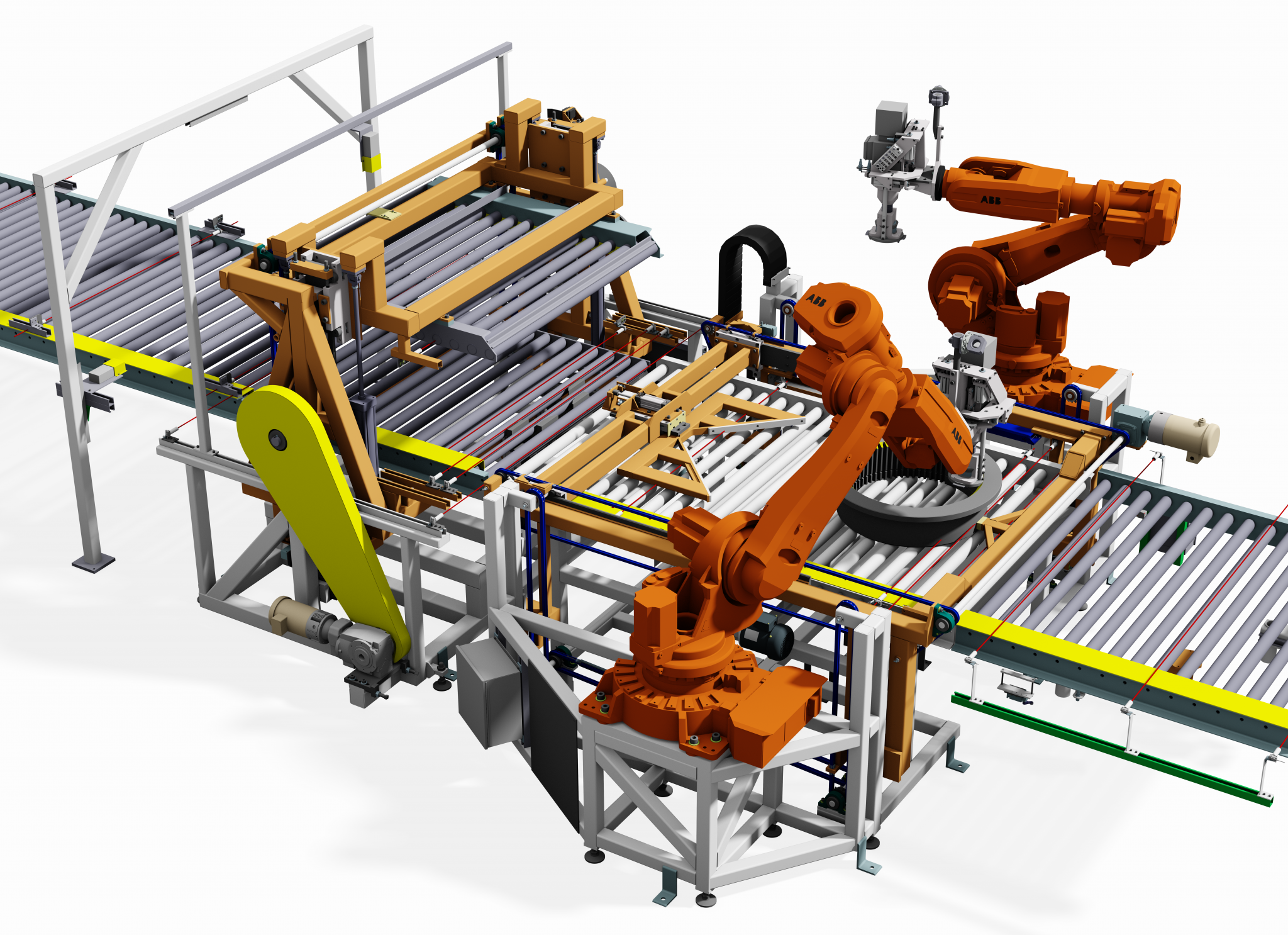

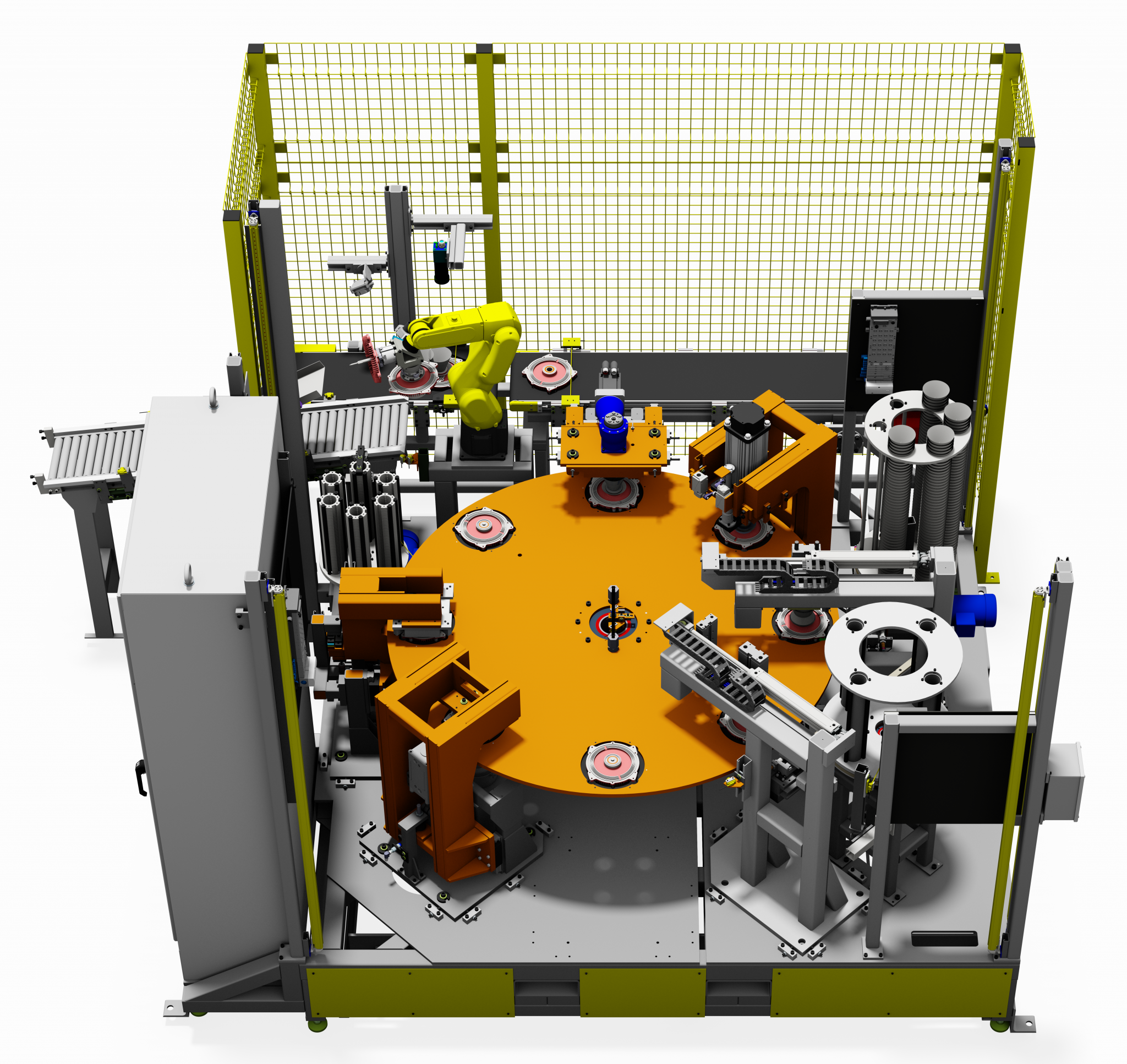

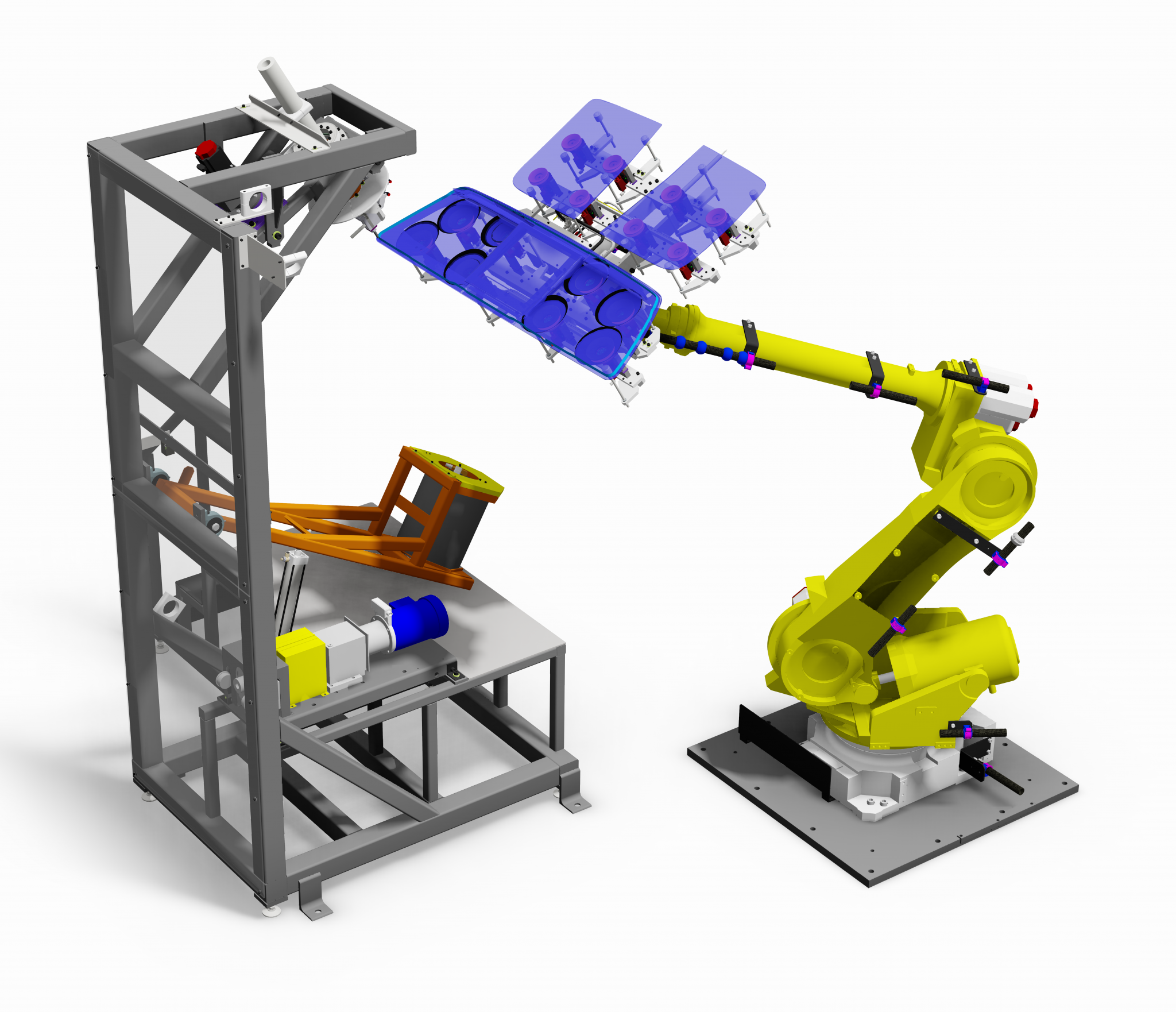

We draw from our wealth of experience and expertise as System Integrators of Automation, Robotic Integration, Assembly Lines, Gauging, Machine Vision & Robotic Guidance, Custom Assembly Machines, Fastening Systems, Fixturing, Custom Conveyors, Metal Marking Systems, Material Handling, Ergonomic Assists, Deburring, Liquid Dispensing, and Headlamp Aiming Systems.

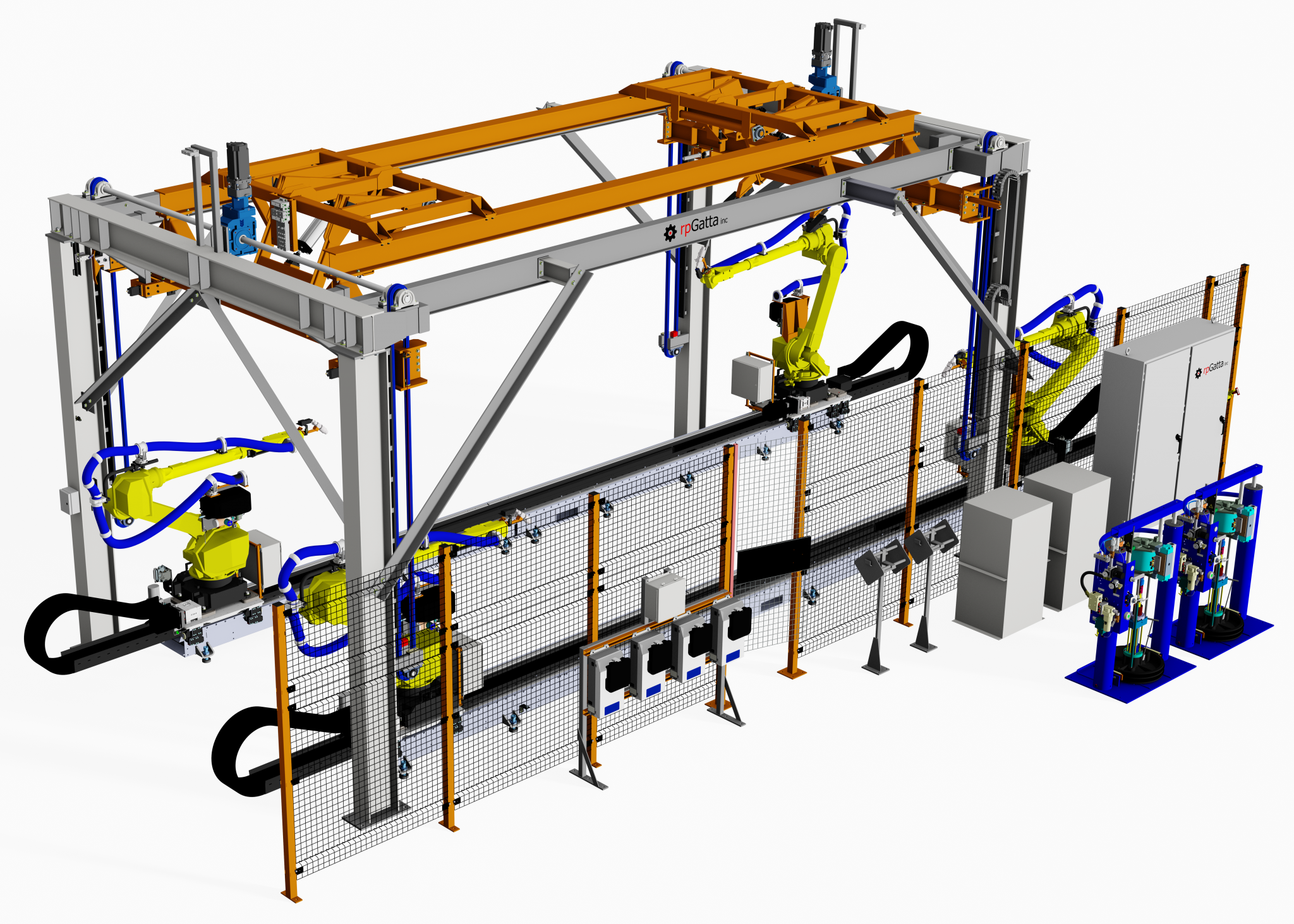

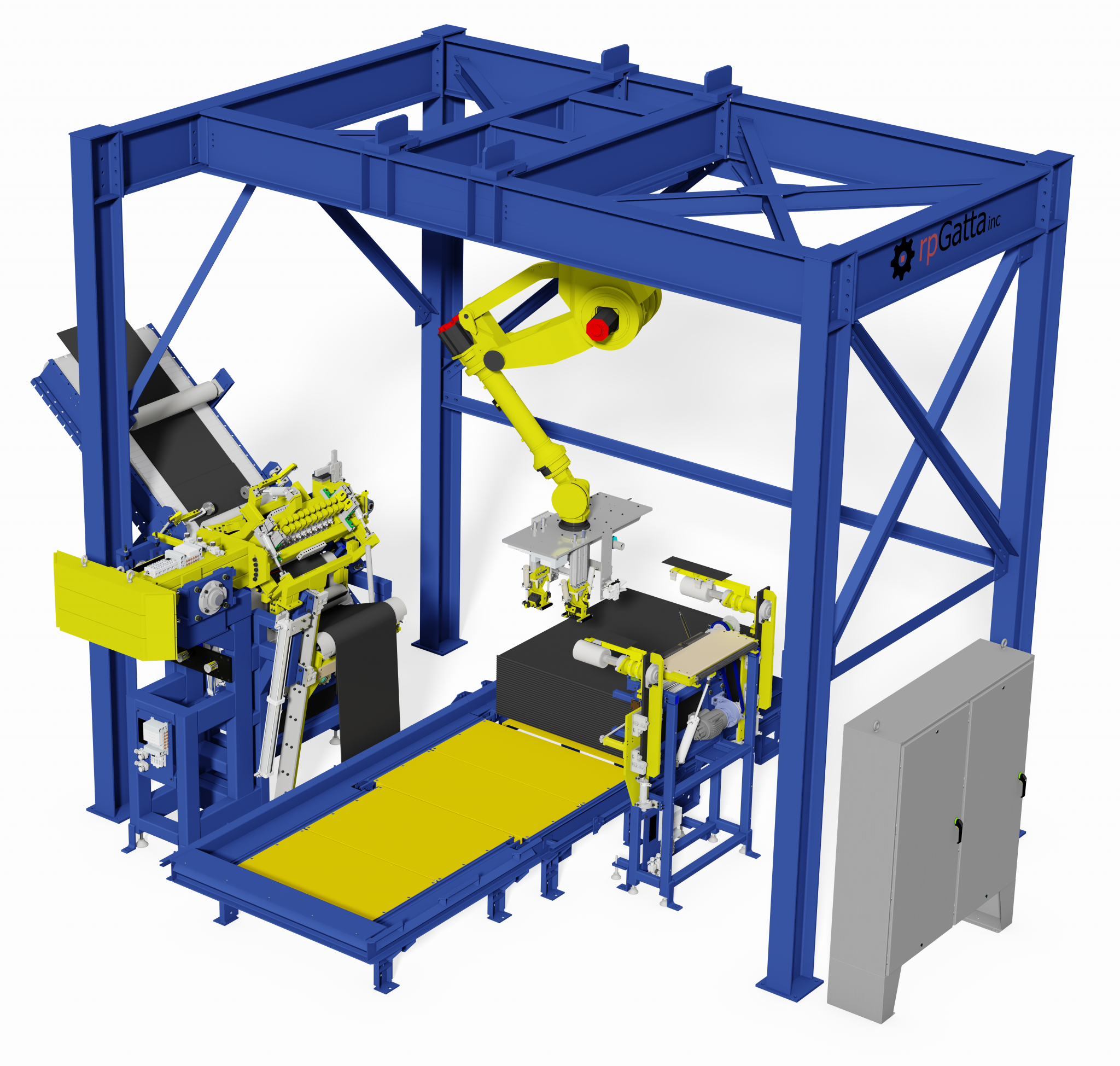

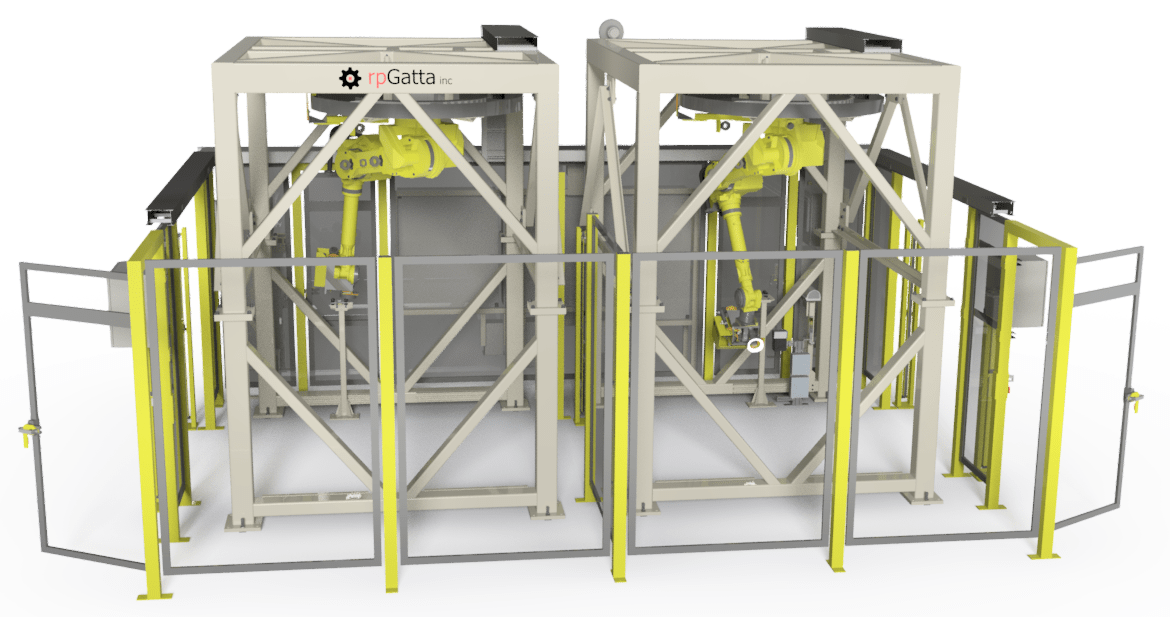

rpGatta, inc is a certified Fanuc, ABB, Motoman, Kawasaki, Kuka, and Epson System Integrator. We custom design automated equipment and robot cells for Assembly, Material Handling, Machining, and Fastening Applications, Vision Guidance, Metal Deburring, High Speed Assembly, Robotic Liquid Dispense Systems, etc.

We are accustomed to tailoring our equipment to meet our customers specific design standards.

Our electrical engineers are well versed in Allen Bradley, GE, Siemens, Mitsubishi, Toyopuc, Yaskawa, and Omron PLC controls. We design and build complete turnkey systems (electrical, controls, and mechanical) in our 56,000 sq. ft. facility, 45,000 sq. ft. of which is dedicated to welding, fabrication, painting, assembly, and testing of equipment.

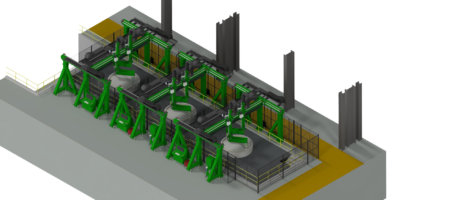

There are five 5-ton capacity overhead electric traveling cranes to aid in machine assembly, and three docks for shipping and receiving. Our mechanical and electrical engineers are proficient with 3D CAD programs (AutoDesk Inventor, Unigraphics, I-Deas, other CAD programs, and AutoCAD Electrical, etc.) rpGatta inc. is ISO 9001:2015/T.E. and ISO 14001:2004 Compliant, and has been awarded Q1 by Ford Motor Company.

Our Process

How We Work

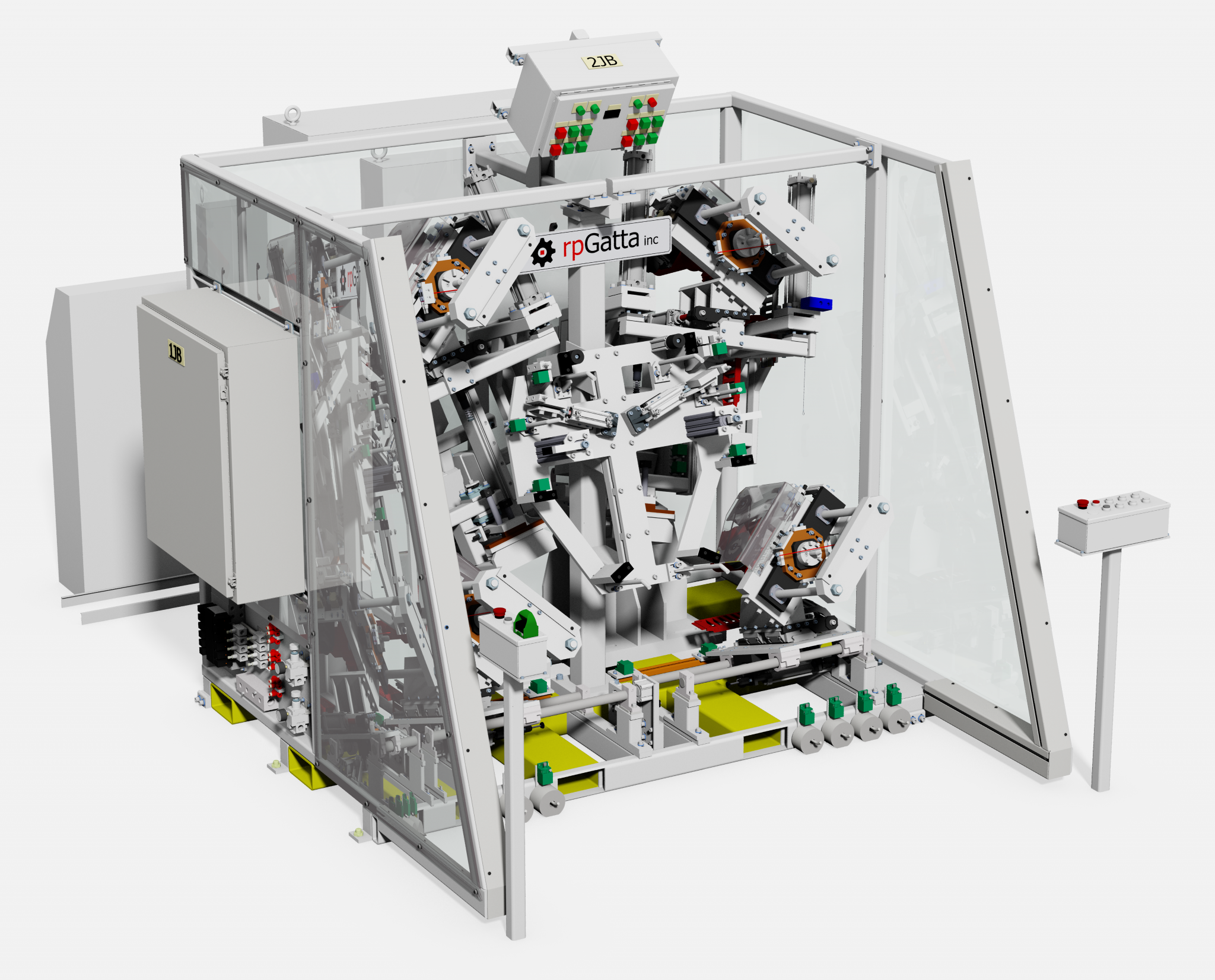

80% of the equipment we design is first-of-kind (prototypes) that must go into full production upon arrival at our customer’s facilities.

We have a minimum of (7) Engineers very involved in overseeing each project: President, Vice President, Mechanical Engineering Supervisor, Electrical Engineering Supervisor, Sales Engineer/Project Manager, Project Mechanical Engineer, and Project Controls Engineer

Very often, we conceptualize the equipment from scratch with only the end purpose requirement provided by our customers.

We engineer the machine or system mechanically, electrically, pneumatically, hydraulically, and the software all in house.

100% Fully Simulated Dynamics Equipment Runoff at rpGatta inc.

We design and build in-house. We never outsource.

The rpGatta Difference

What Separates Us

- All of our equipment is designed, built, and supported in the USA from our facility in Aurora, Ohio

- Since 1985 rpGatta has rigorously developed and built highly engineered, high quality, and reliable turnkey automation and robotic systems to suit our customer’s specific requirements

- 38+ years of successful never-been-done-before projects: we specialize in designing first of a kind / prototype automation and robotic cells that must go into full production upon delivery

- rpGatta is capable simultaneously developing and delivering multiple automated lines >$50,000,000.00

- Proven track record of developing multiple successful and on time projects that have been conceptualized from scratch with only the end purpose or current process provided

- rpGatta line integration experience:

- Dozens of Fluid Dispensing Robotic Systems

- >100 Torque Tools and Multi Spindle Systems Integrated

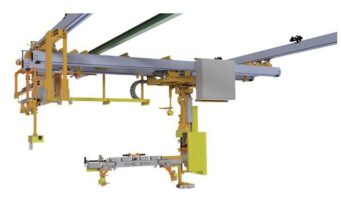

- >1,000’s of feet of linear servo-controlled rack and pinion gantry rail

- >100’s of servo positioning and pressing applications

- >1,000’s of feet of custom conveyors

- Proven Expertise: We draw from a wide variety of experiences over multiple industries and we are accustomed to integrating new technologies and minimizing risk to ensure our success

- All first-class solutions and heavy-duty designs to maximize success

- 100% Fully Simulated Dynamics Equipment Run Off at rpGatta inc

- We never outsource labor, so you can always expect high quality design work and craftsmanship performed in house by rpGatta inc:

- 3D Mechanical Design in Autodesk Inventor

- Electrical, Pneumatic, and Utility Design

- PLC, Servo, HMI Programming

- Vision and Specialized Sensors Integration and Programming

- Robotic Integration and Programming

- Panel Building, Welding, Fabrication, and Light Machining

- Equipment Assembly & Start Up

- rpGatta’s guaranteed commitment to continue to support equipment after final payment and provide phone support after warranty period

Design Build Experience

Capabilities & Integrated Processes

- Manufacturing Line Integration

- Development of Automated Processes

- Line Capacitization

- Tooling Validation and Metrology

- Turn Key Design and Build

- Robot & CNC Integration

- PLC & Controls

- Servo and Motion Controls

- Servo Pressing, Punching, Metal Forming

- Software Development

- Fluid, Sealant, and Adhesive Dispensing

- Fluid Filling and Thermal Management System

- 2D, 3D and Custom Vision

- Vision Inspection and Gauging

- 3D Sensors Integration

- Machine Vision and Robotic Vision Guidance

- Scanning and Metrology

- Moving Assembly Line Tracking and Compliant Location Methods

- Hazardous Location and Explosion Proof System

- Custom Explosion Proof Robotic System

- Intrinsically Safe systems

- Laser Enclosures

- Paint and Fume Booths

- Custom Fume, Dust, and Chip Collection

- Automated Assembly Machines

- Material Handling

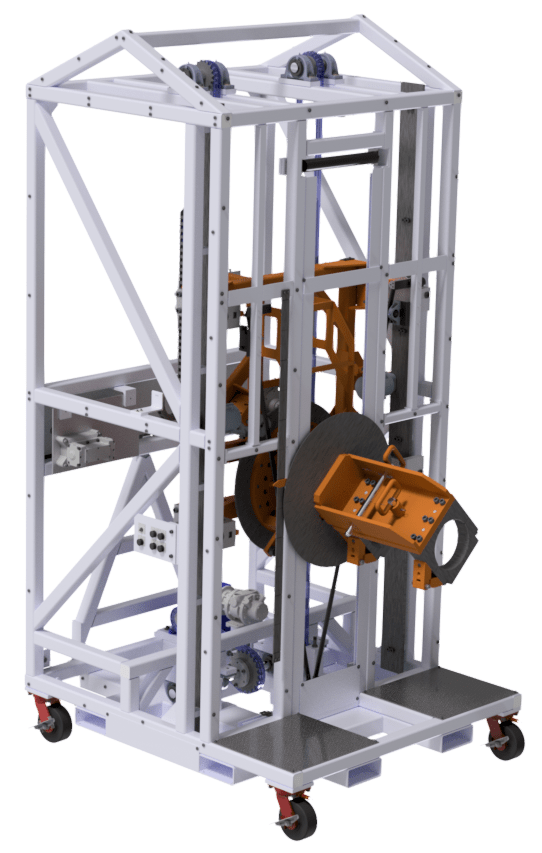

- Smart Ergonomic Assists / Collaborative Machines

- Custom Conveyors

- Fastening and Automated Fastener Feeding

- Part Marking and Data Tracking

- Laser Welding, Cutting, Cladding, Marking

- Plasma Ablation and Surface Preparation

- Deburring and Sanding

- Depainting and Metal Processing

- Test Systems:

- Gauging & Metrology

- Leak Test

- End of Line Testing

- Power Electronic Test

- NVH and Dyno Testing

- Headlamp Aiming & ADAS Calibration

Read Our Latest News & Updates

What's Happening at rpGatta

Kent State University Mechatronics

We were happy to host a tour for a group of KSU Mechatronics students studying…

2022 Project Updates

In 2022, rpGatta designed and built an inverter assembly line, multiple bushing presses, headlamp aiming…

rpGatta Designed and Built a Custom Robot Arm

We came across an application where a commercial multi-axis robot did not have the reach…

2021 Project Updates

We recently installed our drive unit and dual power inverter module assembly lines that consisted…

Experienced integrators of the following:

SYSTEM PARTNERS: