rpGatta HD Slides

HD Slides Brochure

HD Slides Data Sheets

HD Slides Overview

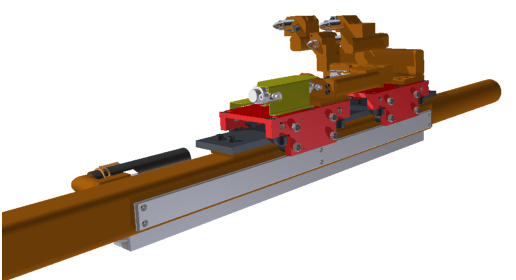

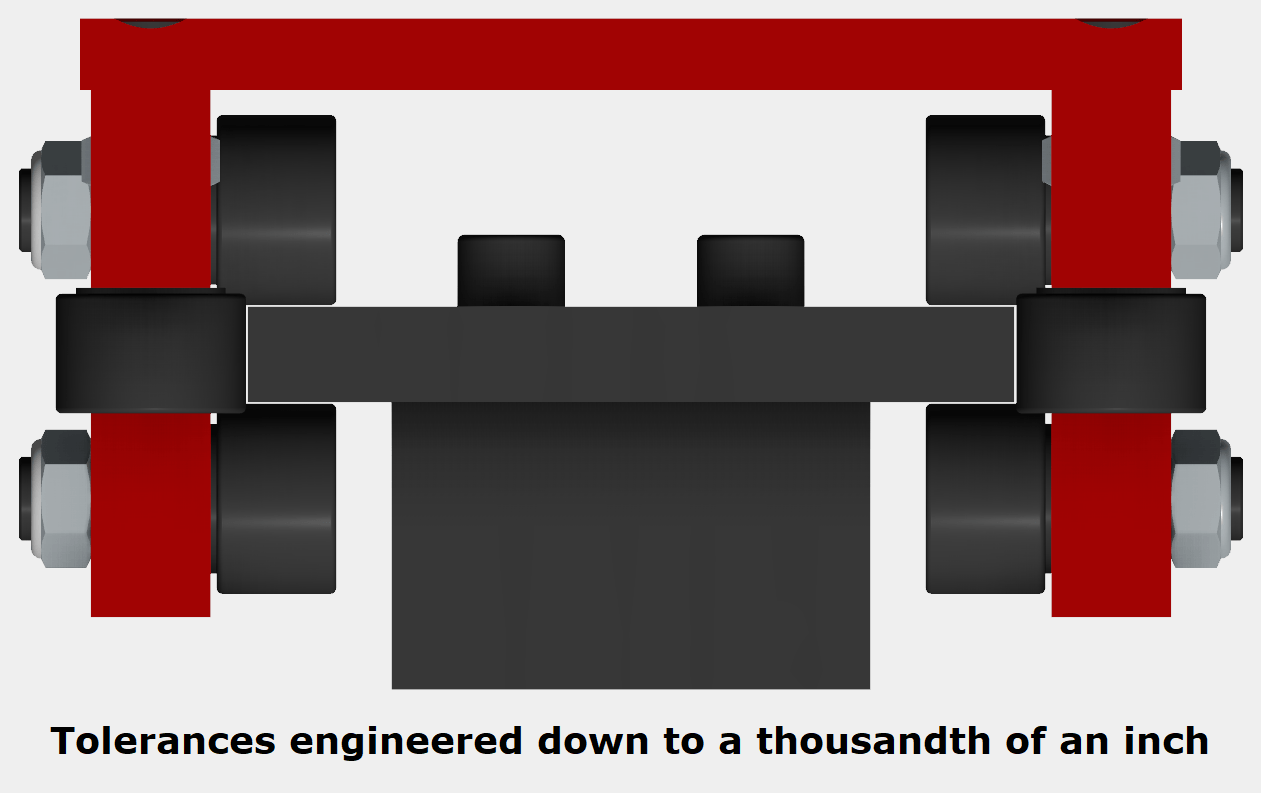

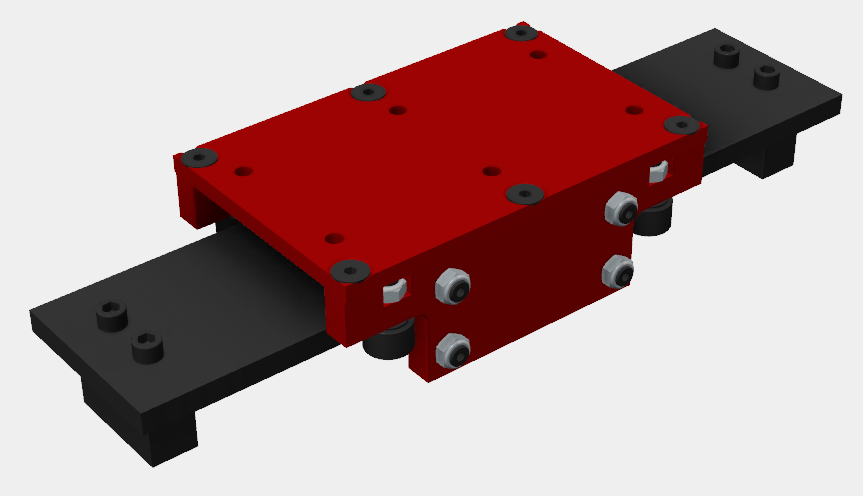

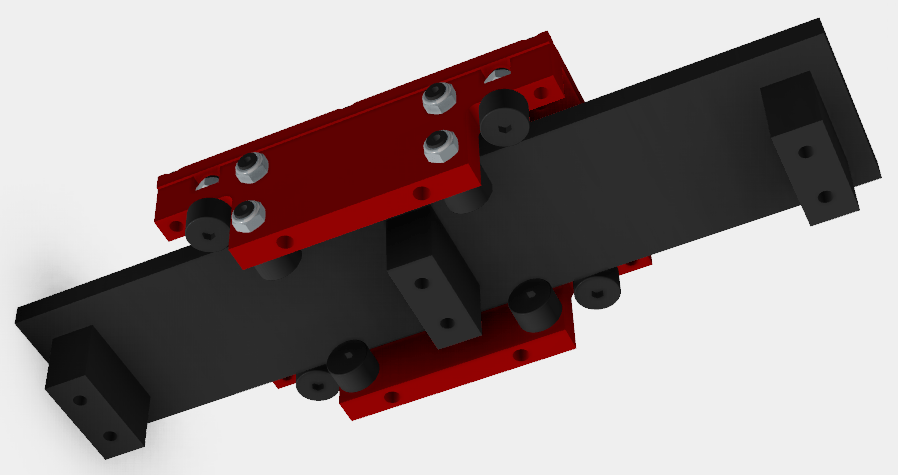

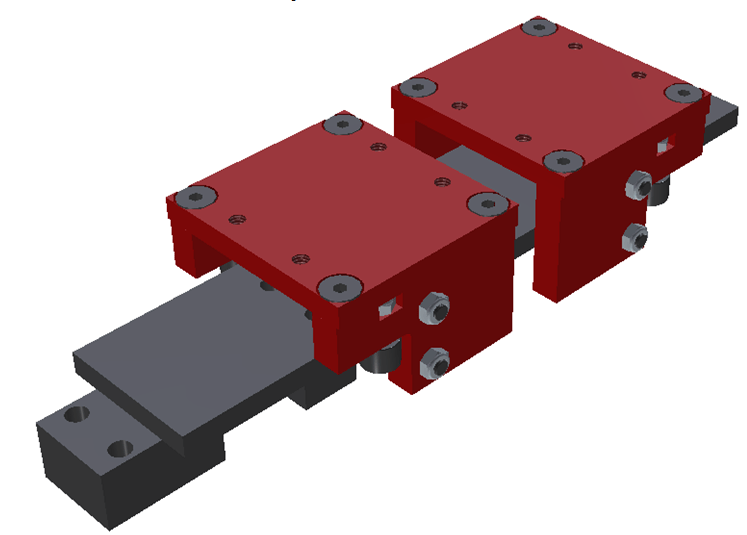

rpGatta’s Heavy Duty, low maintenance, high capacity slides are designed for harsh environments that do not require precision mounting surfaces. The slide assemblies are constructed of a stock size hardened and ground rail along with high strength aluminum saddles with durable heavy load carrying needle roller bearings.

HD Slides will perform equally in any orientation and whether the saddle or the rail is the traveling component. Versatile mounting holes are provided on both the saddles and the rails. Applications requiring high cantilevered loads are well suited for these high moment capacity slides. HD Slides will outperform profile or shaft type anti-friction slides in high production assembly and heavy manufacturing operations where machine up time is a must.

Why HD Slides Are Superior

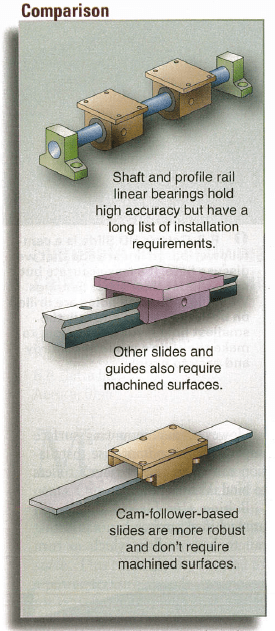

Bearing contamination causes bearing failures. The HD Slide’s design inherently separates contaminants that will collect on the rail in manufacturing environments from the roller’s bearing needles because the outer race of the sealed needle bearing roller is what engages the rail. On profile rail and shaft type anti-friction slides, the bearing balls engage directly with the profile rail and shafting. When contaminants get past the seals, the bearings are corrupted.

Because HD Slides do not require precision mounting surfaces, milling of mounting surfaces are not required. The elimination of machining not only significantly saves money, but provides design flexibility, particularly on large welded frames.

From a heavy manufacturing environment’s practical perspective, the mounting holes provided in the profile rail and linear shaft slides are too small. The smallest size mounting hole you will find in an HD Slide is for a 1/4″ diameter bolt.

When removing the HD Slide saddle from the rail, all components remain attached. With a profile type slide, if you remove the saddle, the bearing balls will release from the saddle bearing and are easily lost. When these balls are not replaced when the saddle is reassembled to the rail, the bearing life is significantly reduced.

HD Slides components are available in a number of different materials to meet your equipment requirements. The slide saddles are available in both steel and high strength aluminum. The rails are available in hardened and ground steel for high duty cycle applications or cold rolled steel standard bar stock for low duty cycle and lower budget applications. Moreover, Stainless Steel HD Slide Assemblies are available when corrosion resistant machine components are specified. HD Slides have a Two Year Limited Warranty.

HD Slides Example Applications

Cockpit Module Lift – Pin Slide:

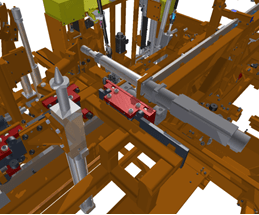

Fastening Equipment – Horizontal Tool Slide:

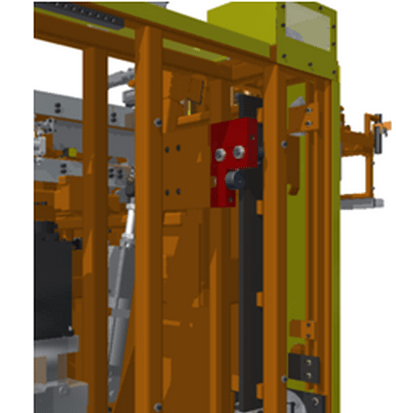

Vertical Lift Guide: