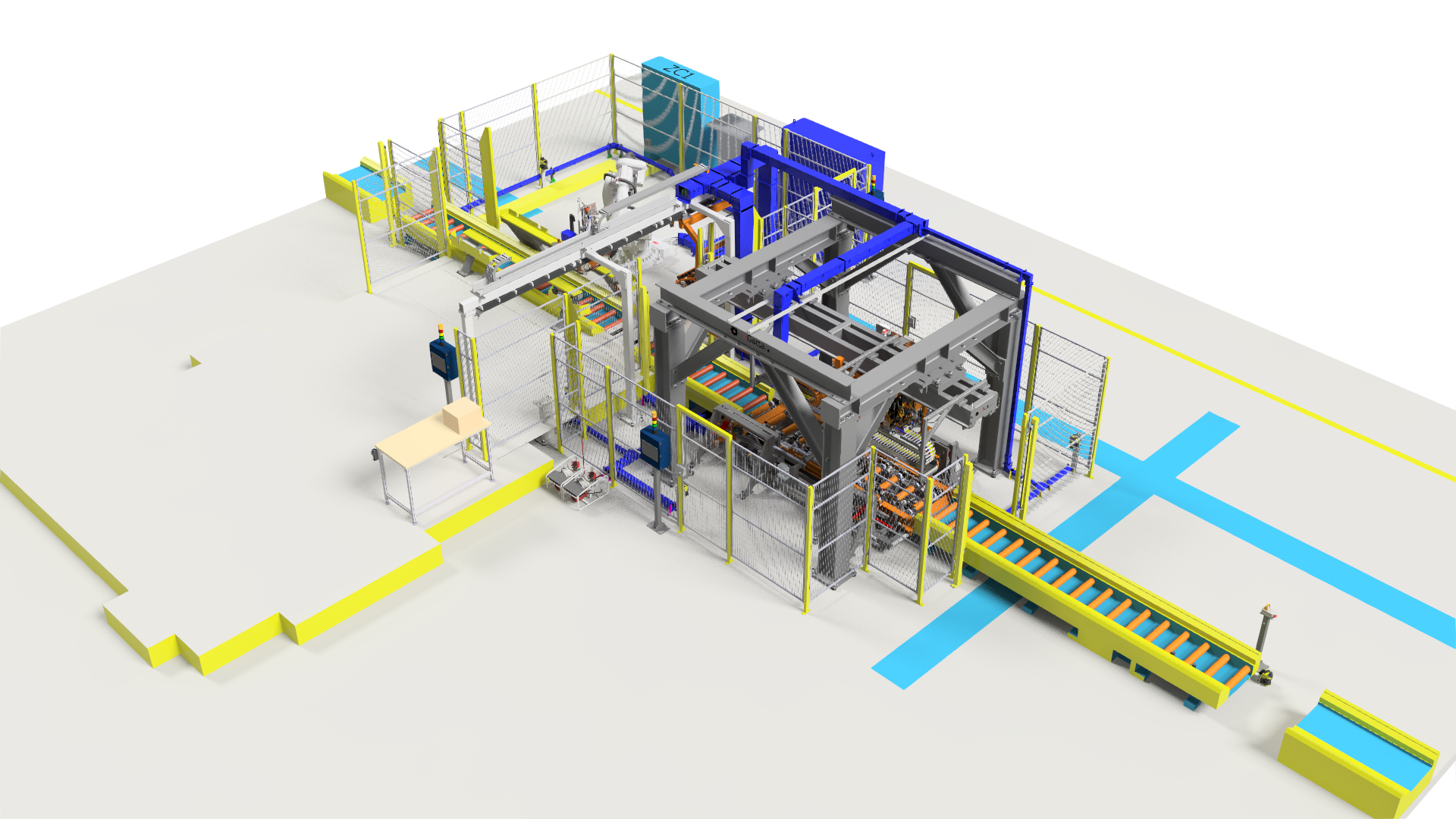

Assembly Line Development and Integration

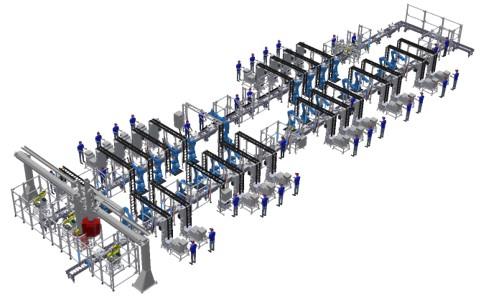

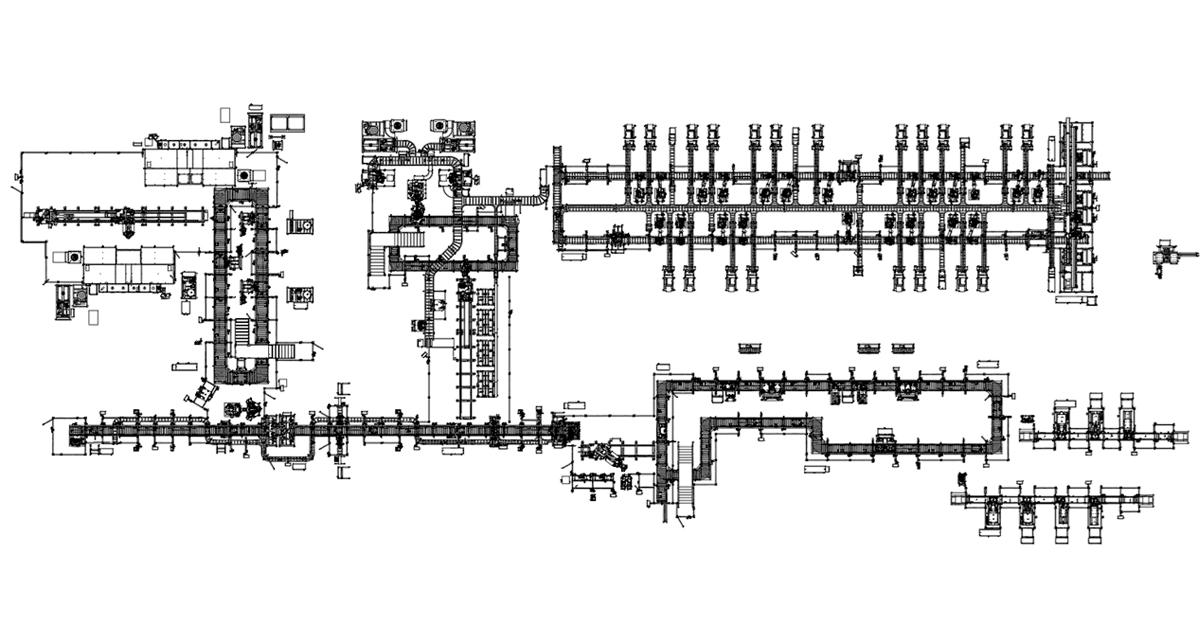

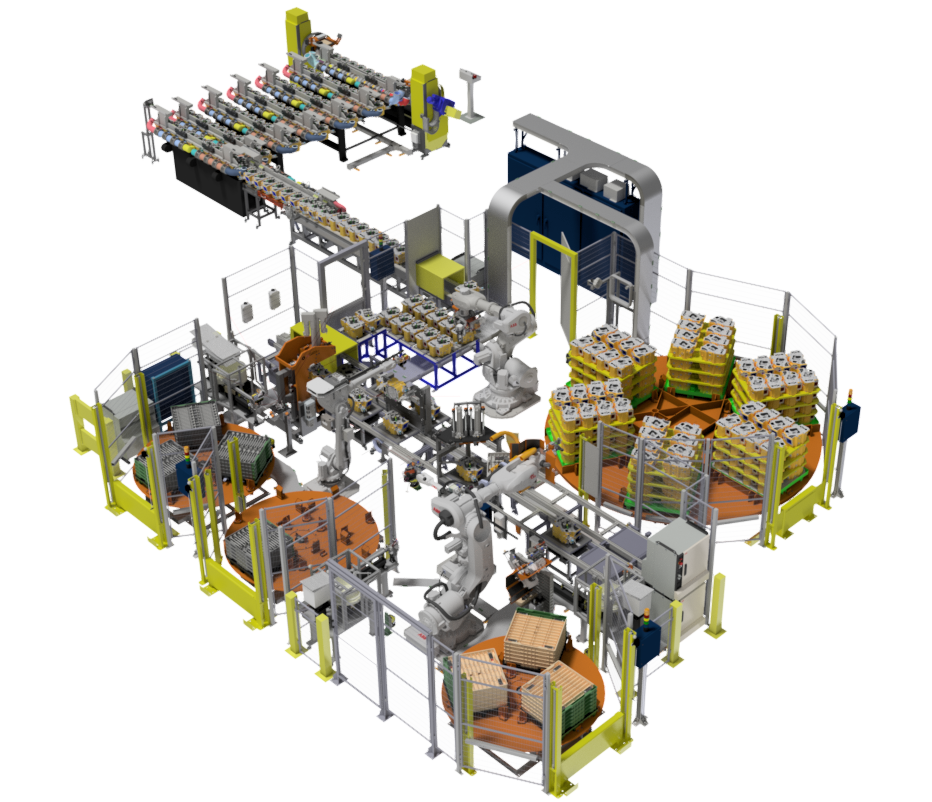

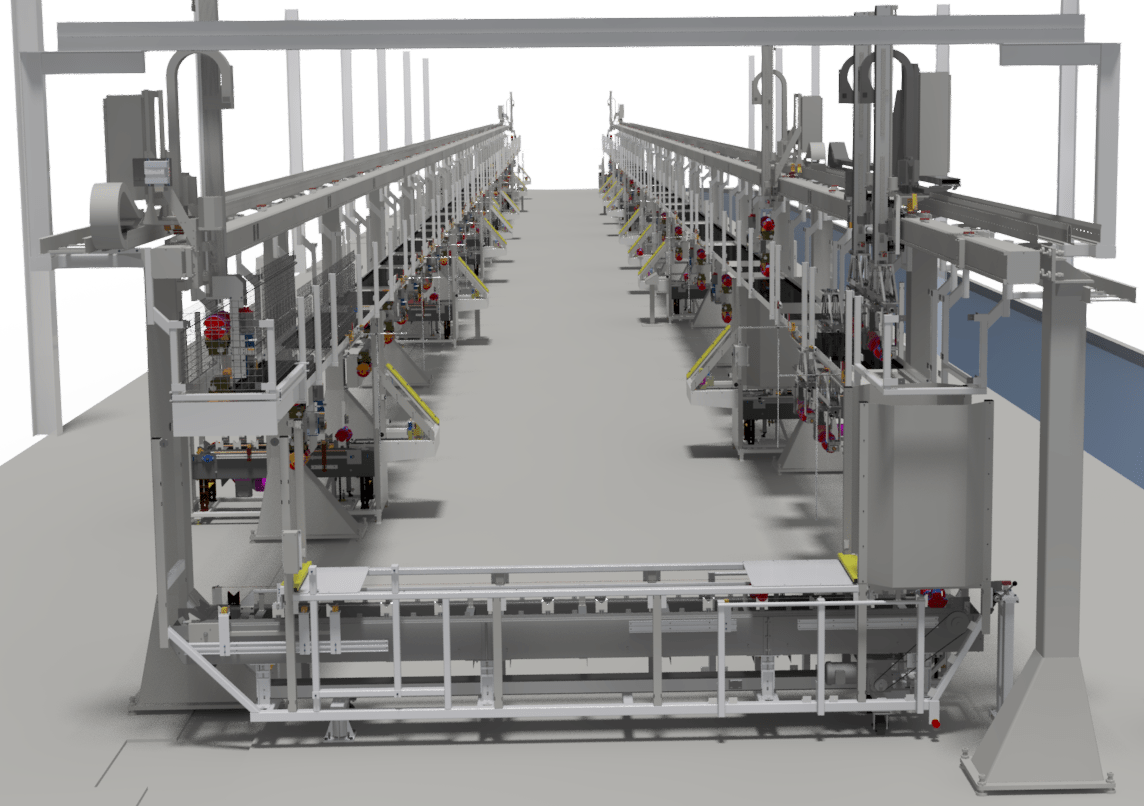

Crankshaft Material Handling Gantry

Features:

- 650 Foot Long 17 axis Servo Gantry Crankshaft Loading System

- 14-Crankshaft Loading, Buffer, Crossover and Unload Conveyors

- Multiple Quality Control Takeout Stations

- 17 Operator HMIs

- Integration of dozens of unique machines including bar code marking, data, and part tracking through grinders, lathes, balancers, hardeners, washers, gauges, mills, laser markers, conveyors, etc.

Check out this this Youtube video we did with Fanuc on our Crankshaft Machining Center Servo Gantry Loading System.

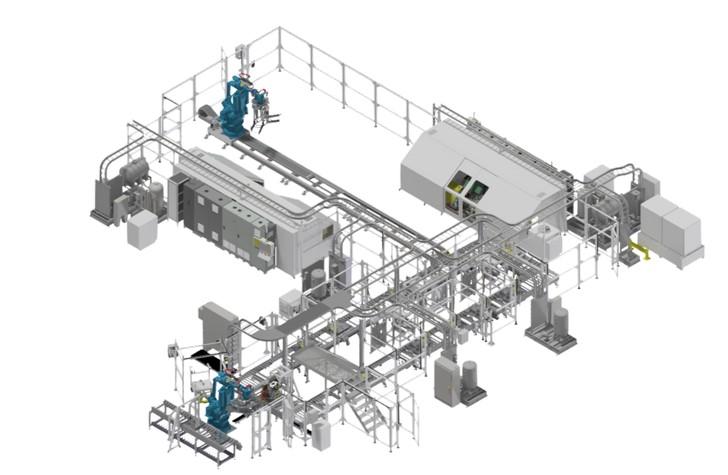

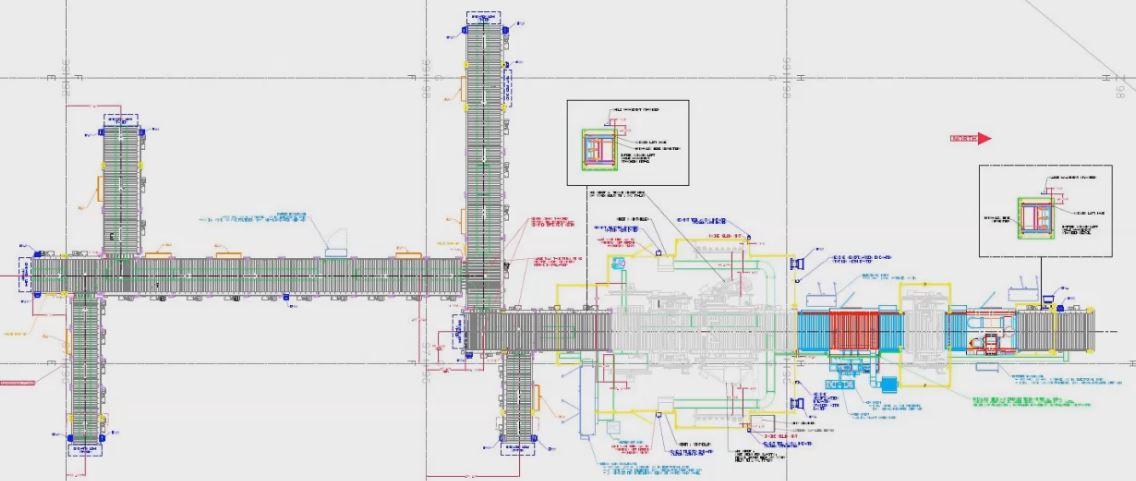

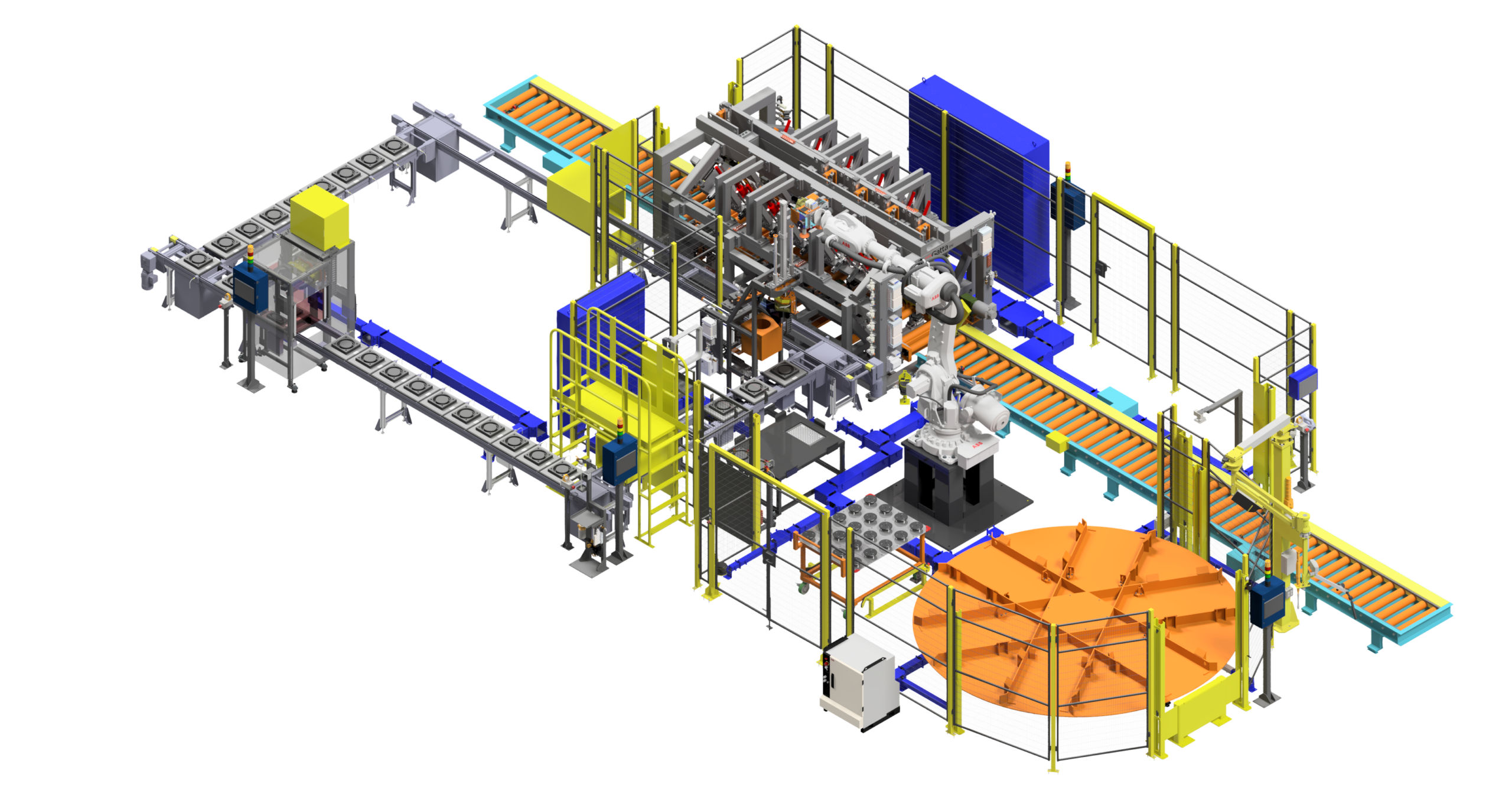

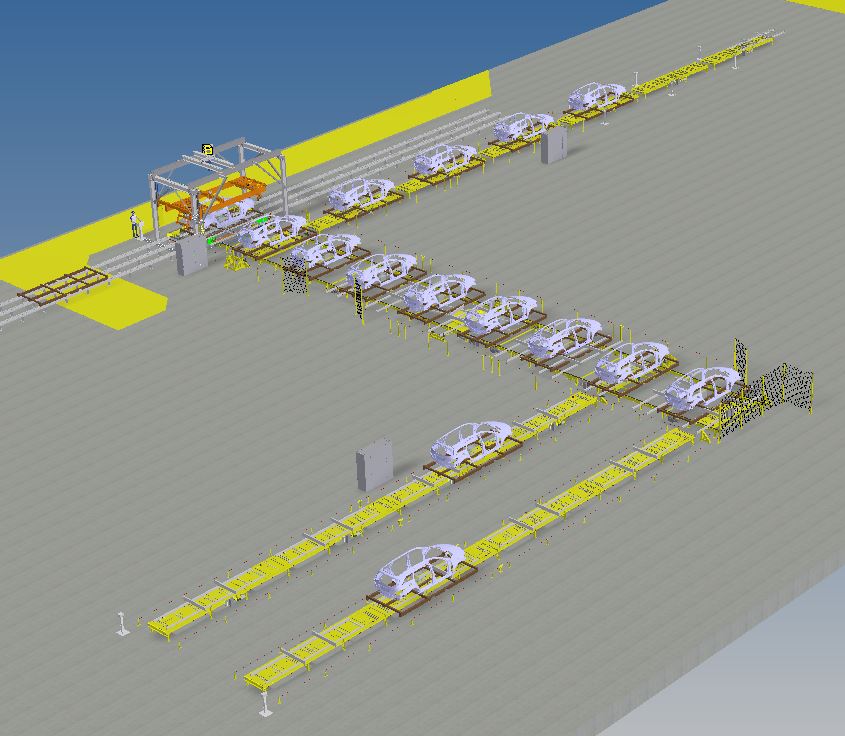

Vehicle Accumulation and Transfer Line

Features:

- Body Transfer System

- 470 Feet Of Driven Roller Conveyor

- Two-Strand Side Winders

- Vehicle Body Lift

- Skid Loading System

- Painted Body Load And Unload

- 2-Hydraulic Scissor Lifts

- Lift And Transfers Between Steel & Wood Skids

- Turntable To Rotate Skids 180°

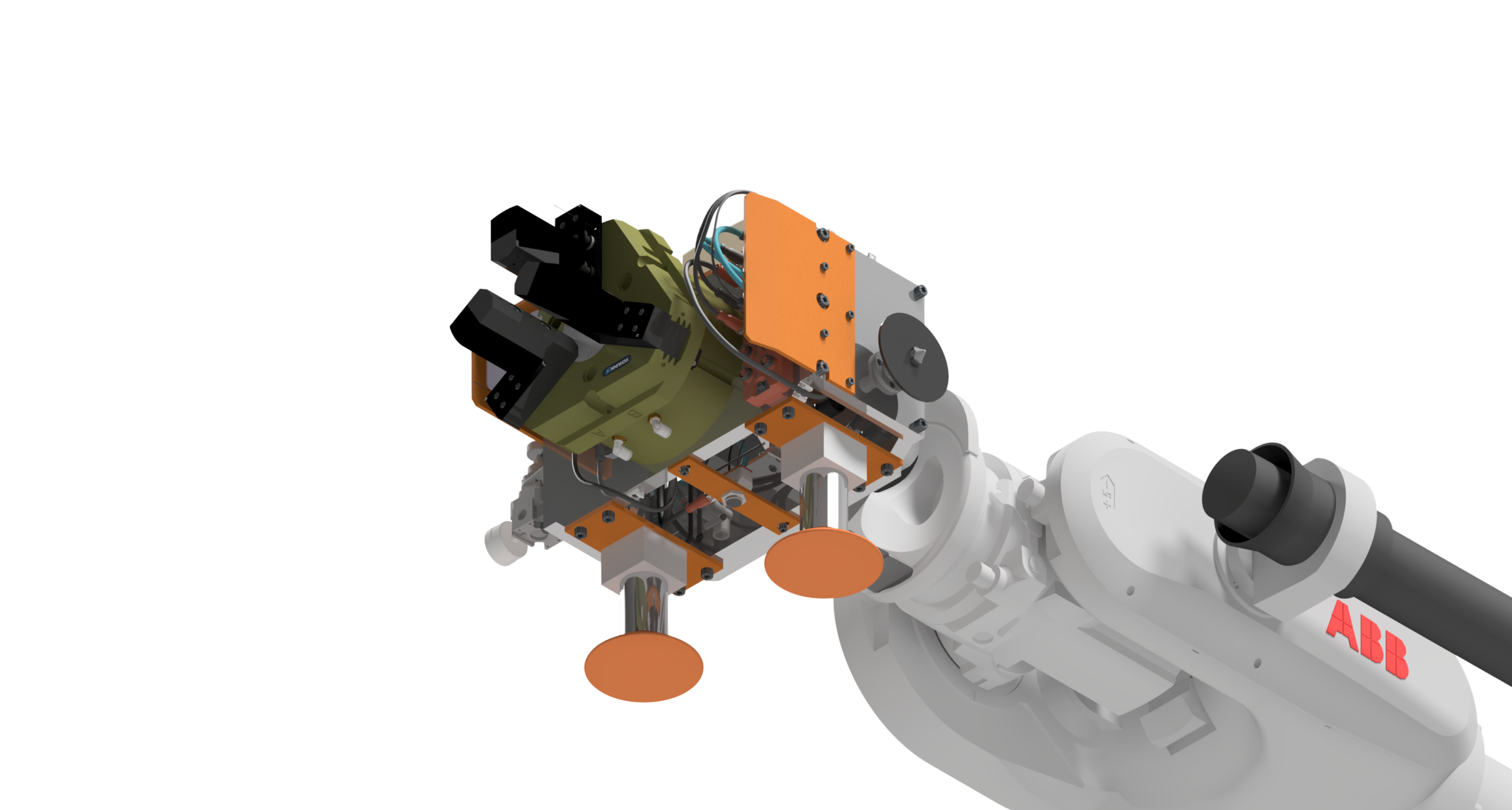

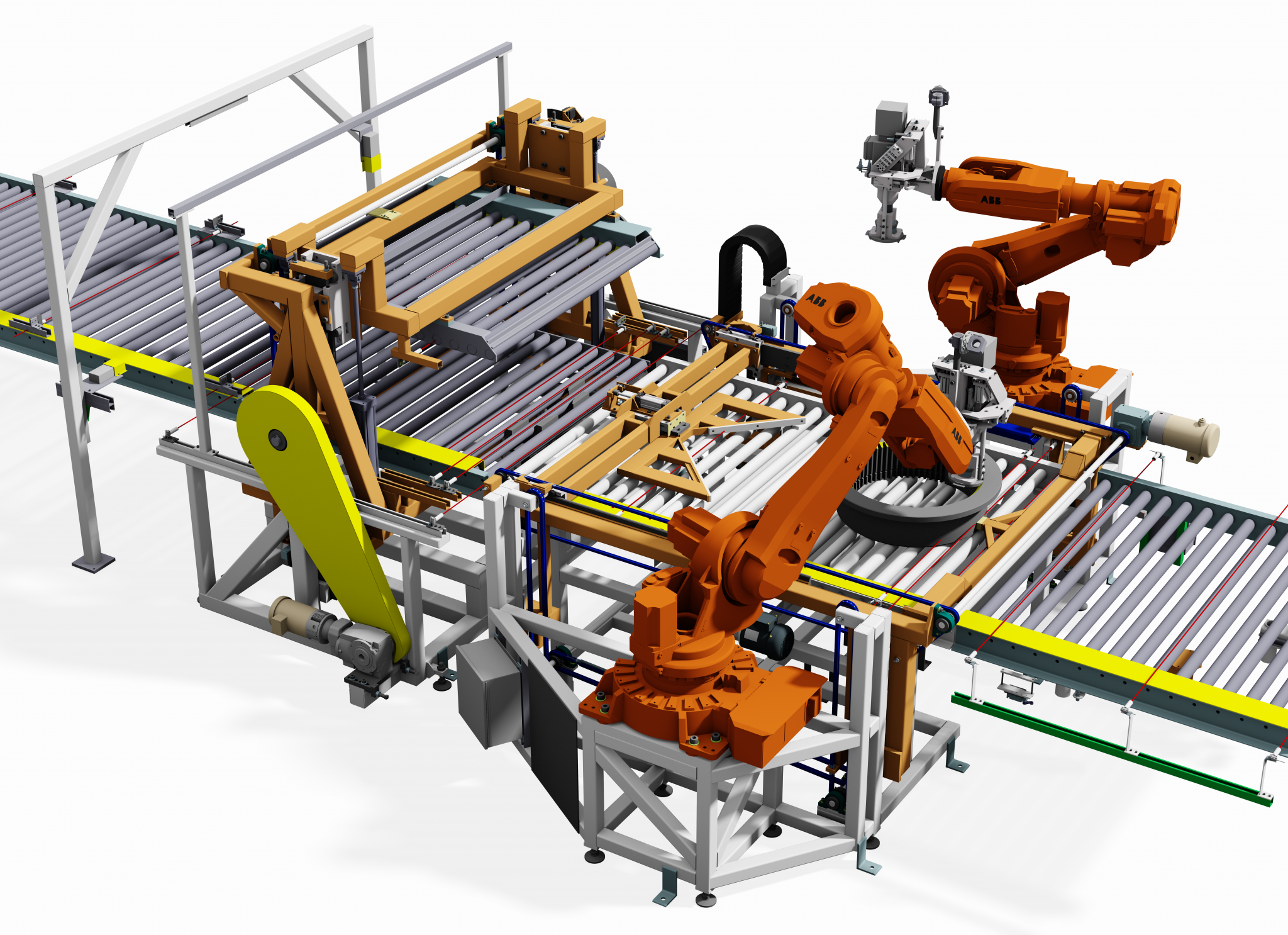

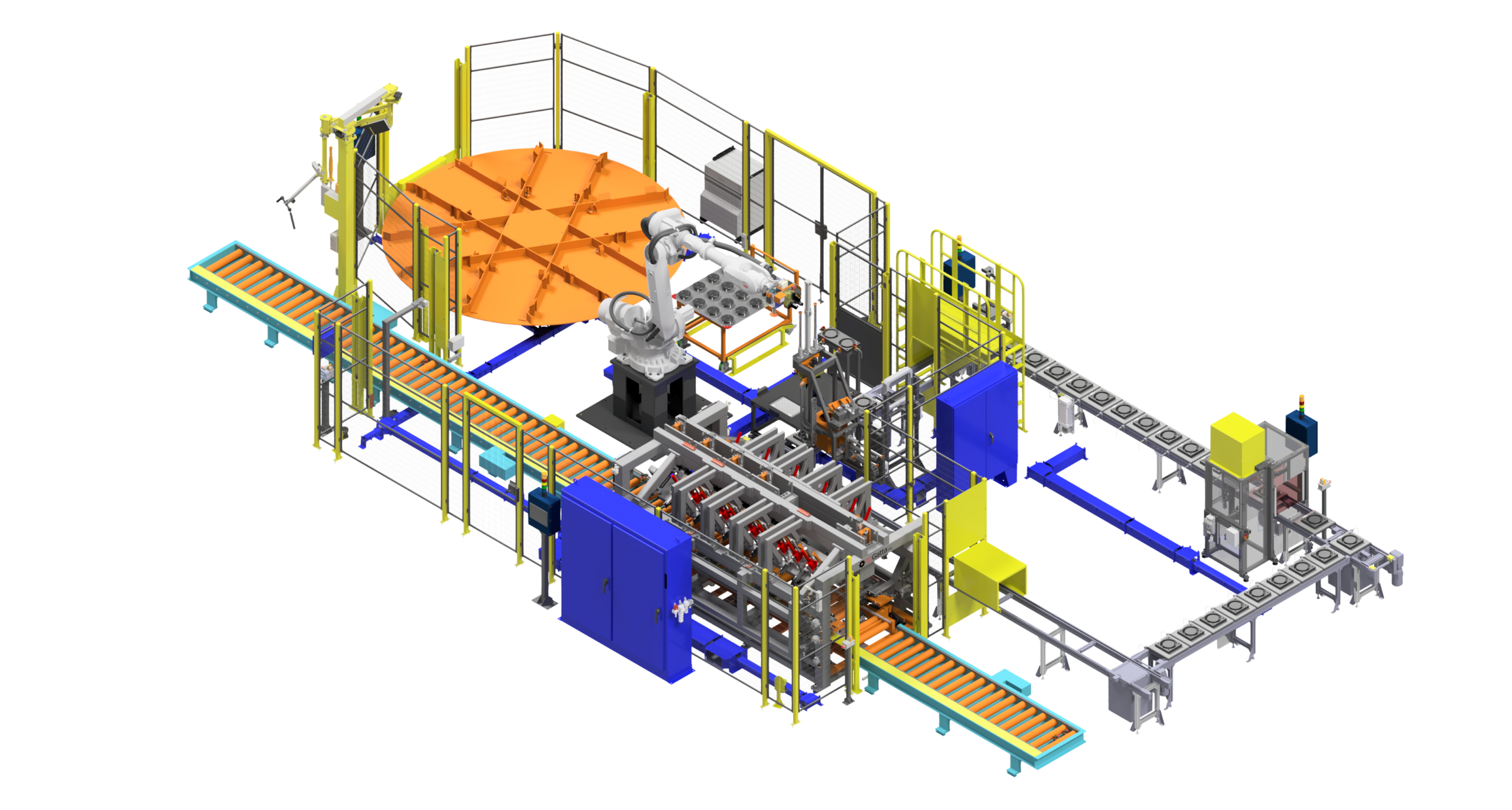

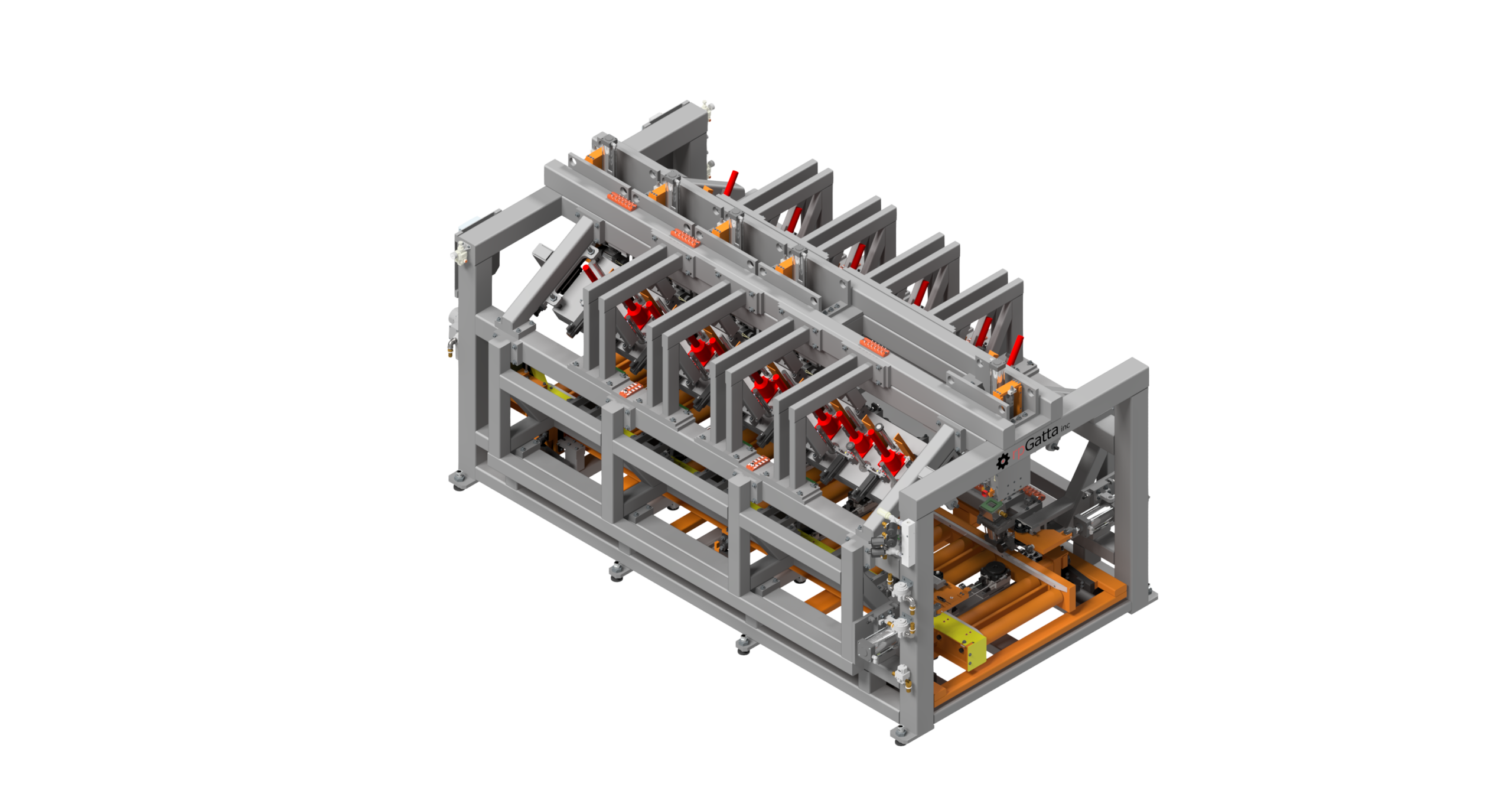

Bearing Cap Assembly

Features:

- Utilizes one ABB robot

- Custom end effector featuring custom grippers, torque tools, probe, and profilometer.

- Custom engine block lift and locate mechanism

- Accommodates multiple engine sizes

- Utilizes custom hydraulic system and eight torque tools for stud tensioning, stud rundown, and crosstie bolt pre + final torque

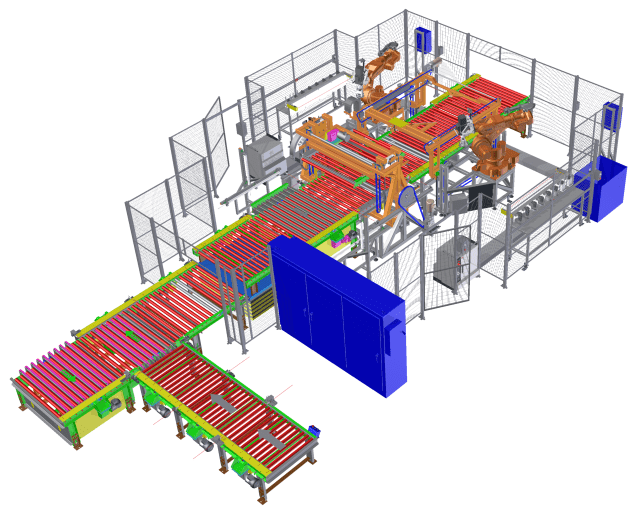

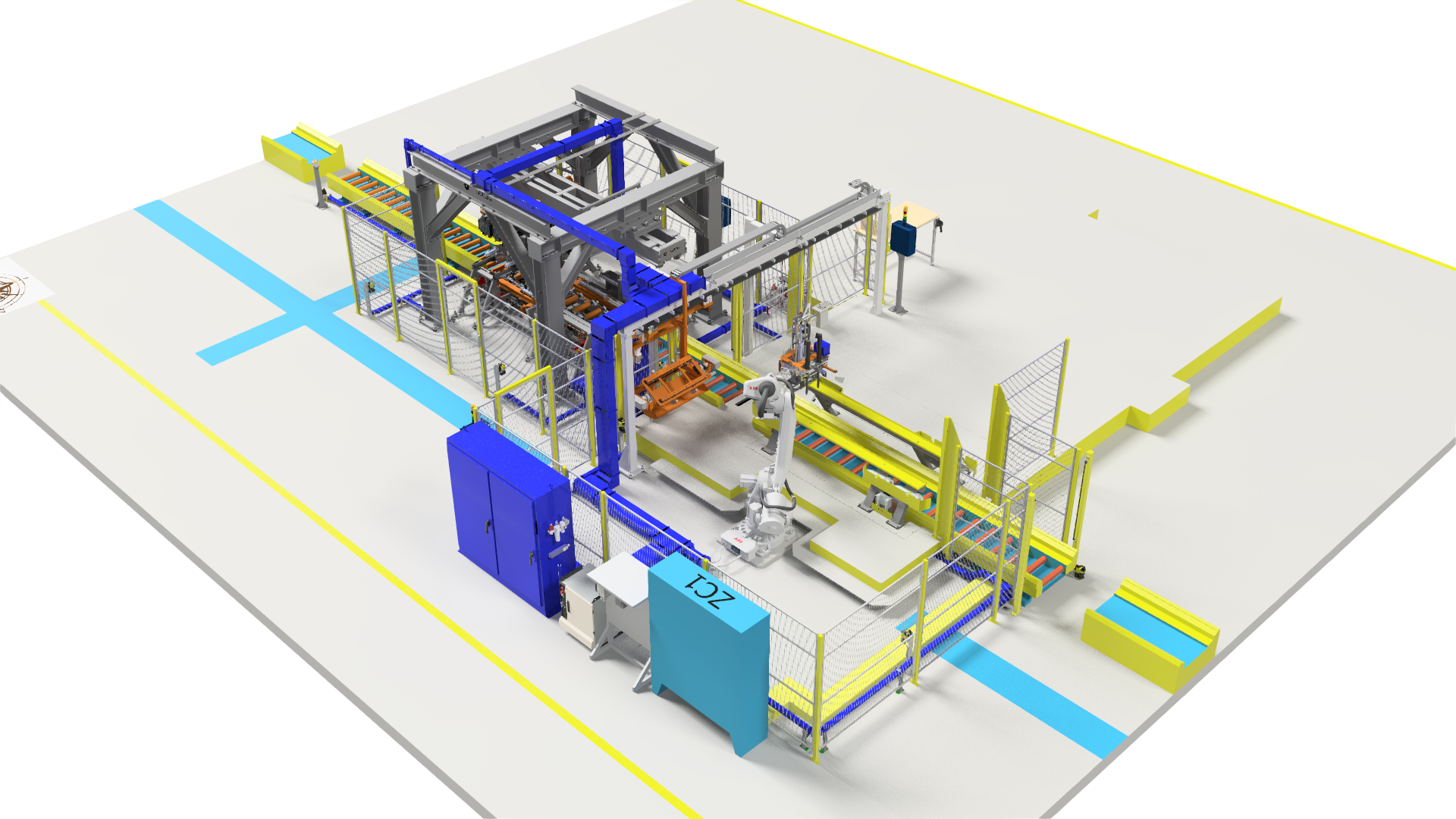

Features:

- Utilizes one ABB Material Handling Robot

- Vision Assisted Robot Pick and Place

- Custom end effector with gripper, vacuum cups, and touch-off probe

- Automatic engine block touch-off and frame teach

- Accommodates four different engine sizes with a multitude of different liner types

- Utilizes a liner prep conveyor loop with automatic and manual stations

- Utilizes liner accumulation turntable to hold multiple part numbers for builds

- Barcode and combustion face inspection camera

- Plenum Plug inspection camera

- Profilometer liner inspection

- Liner auto-lube station

- Liner repair and reintroduction station

- End of Line Leak Test to test various block sealing points

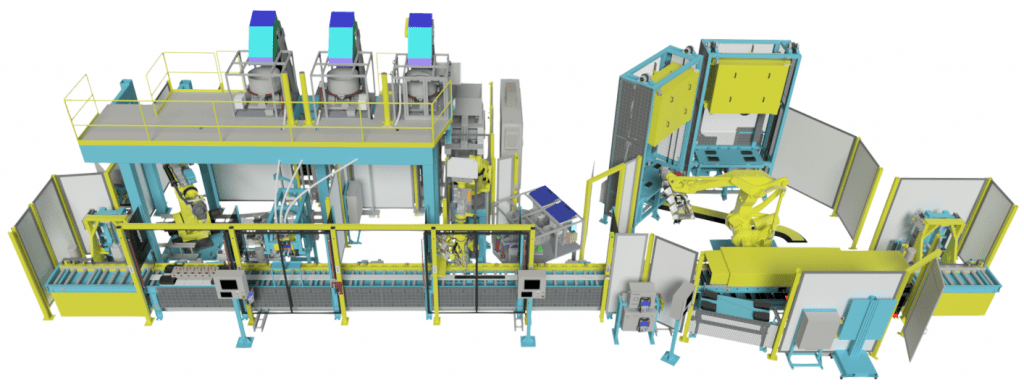

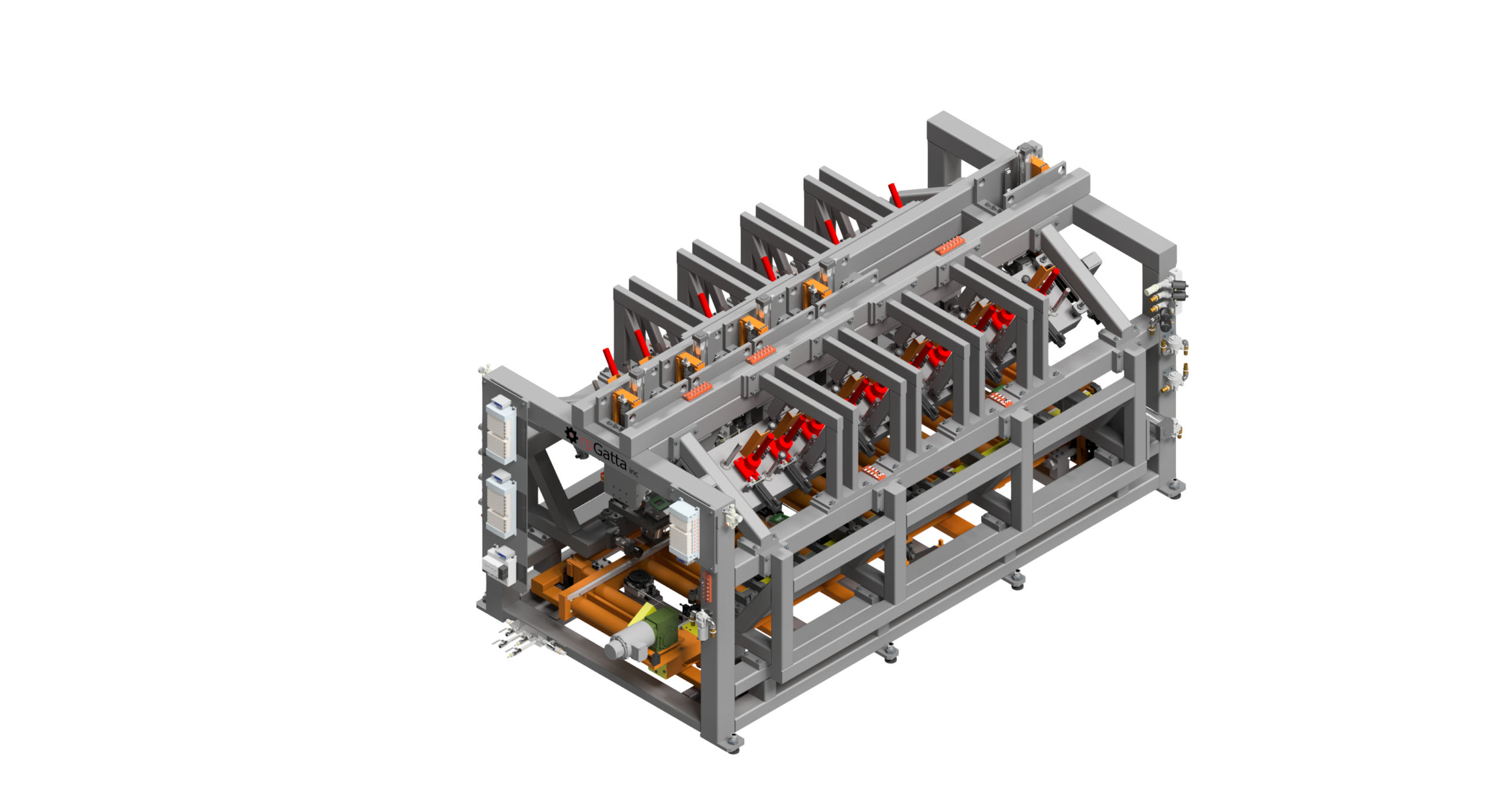

Leak Test Features:

- Accepts four different engine sizes and number of cylinders

- Custom Engine Lift and Locate

- 20 servo presses for liner press and seal

- PLC based leak test

- Configurable press and test parameters based on model

- Gross leak detection and early stability cutoff for time efficiency

- Graphical Representations of Press and Leak information

- Press and Leak Test Data Collection including:

- Individual Liner Press Force and depth

- Leak Test pressure/ pressure delta and times for each stage (fast fill, fill, stabilize, test)

- Ability to repair and reintroduce a completed block from last conveyor station back into press and leak test