Deburring Systems

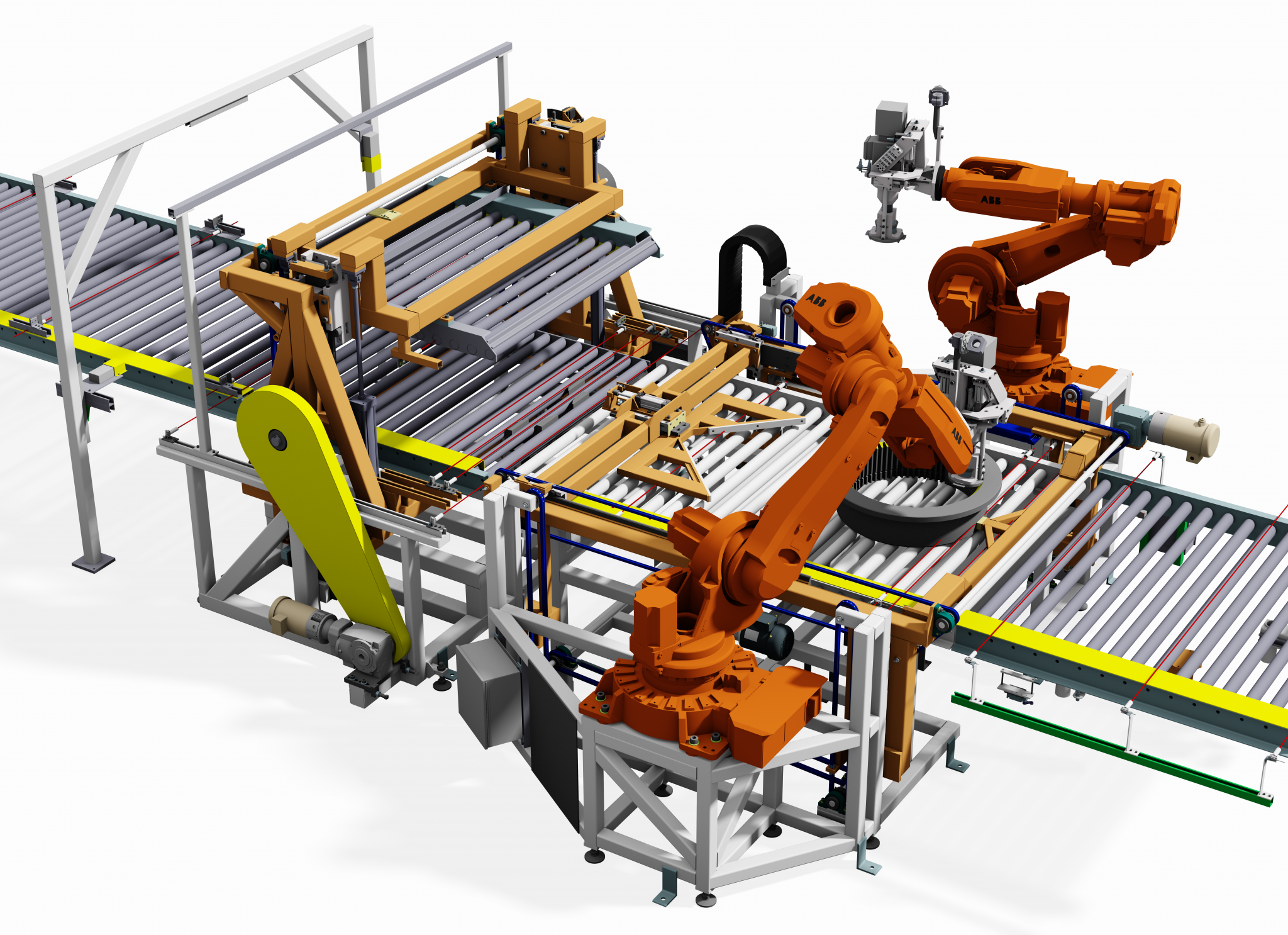

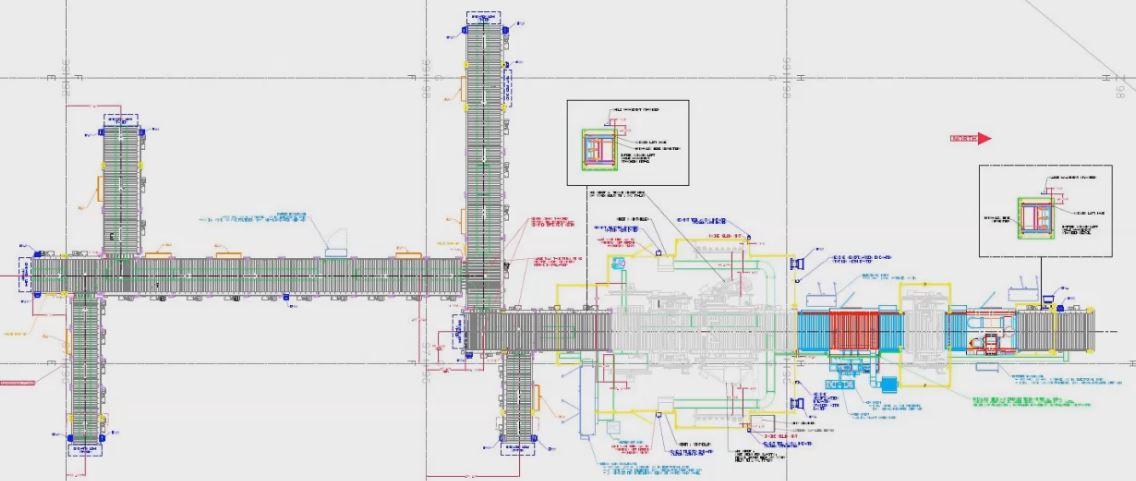

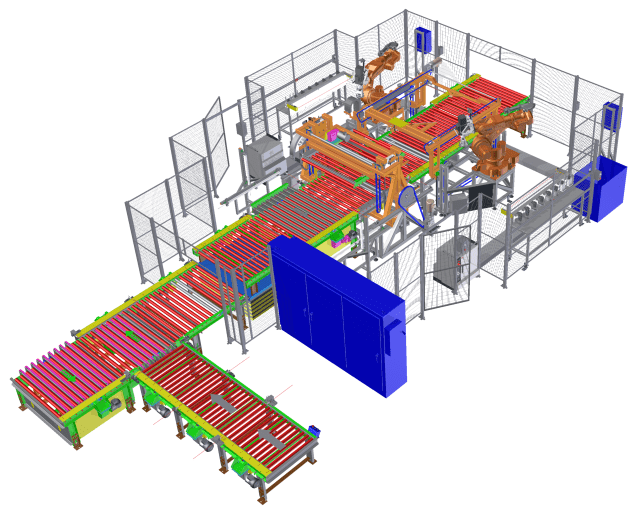

Robotic Ring Gear Deburring Line

Features:

- A driven roller conveyor feed parts into the deburring cell from multiple upstream processes

- Automatic part detection identifies inbound parts and configures the system for automatic processing of the inbound part

- Inbound and outbound roll-over stations allow for deburring on both sides of the part, regardless of how it is conveyed into the cell

- Robotic deburring station utilizes two robots and automatic tool changers for on-the-fly tool changes

- Integrated washer and blow-off system for cleaning of parts after deburring process

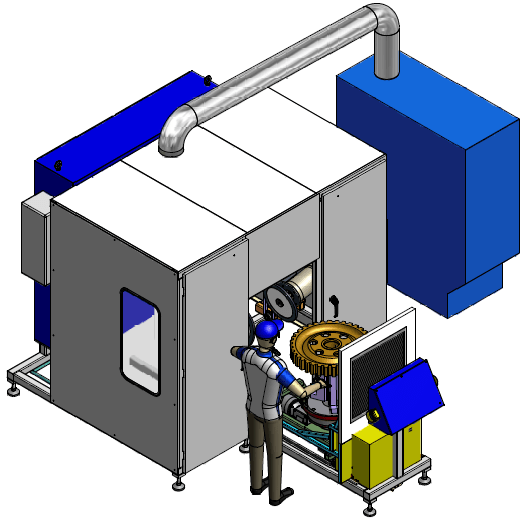

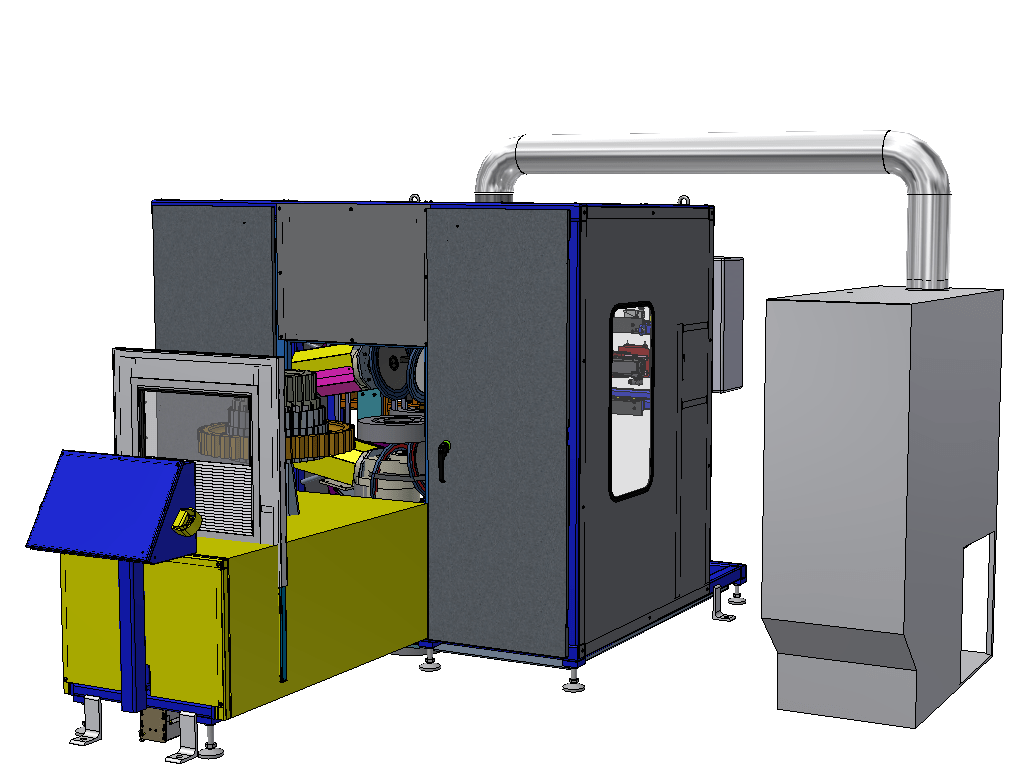

Universal Servo Controlled Planet and Sun Gear Deburring System

Features:

- Universal Inner Diameter Locating and Clamping Mechanism adjusts to accommodate a large range of Inner Diameters on the Turntable without operator tool changes

- (2) Brushes engage the top surface, on opposing sides of the gear

- (2) Brushes engage the bottom surface, on opposing sides of the gear

- A Force Feedback System is utilized to adjust the amount of pressure that is exerted on the Brushes as they engage the Gear

- Servo Driven Feed Slides for each of the (4) Deburr Brushes

- Motor current on each of the Deburr Brushes is monitored and the Servo Driven Feed Slides adjust to the desired parameters programmed in the Recipe

- User Definable Recipe for Each Gear: ID/OD, Brush RPM, Brush Contact Pressure

- Integrated Dust Collection Equipment