Dispensing Systems

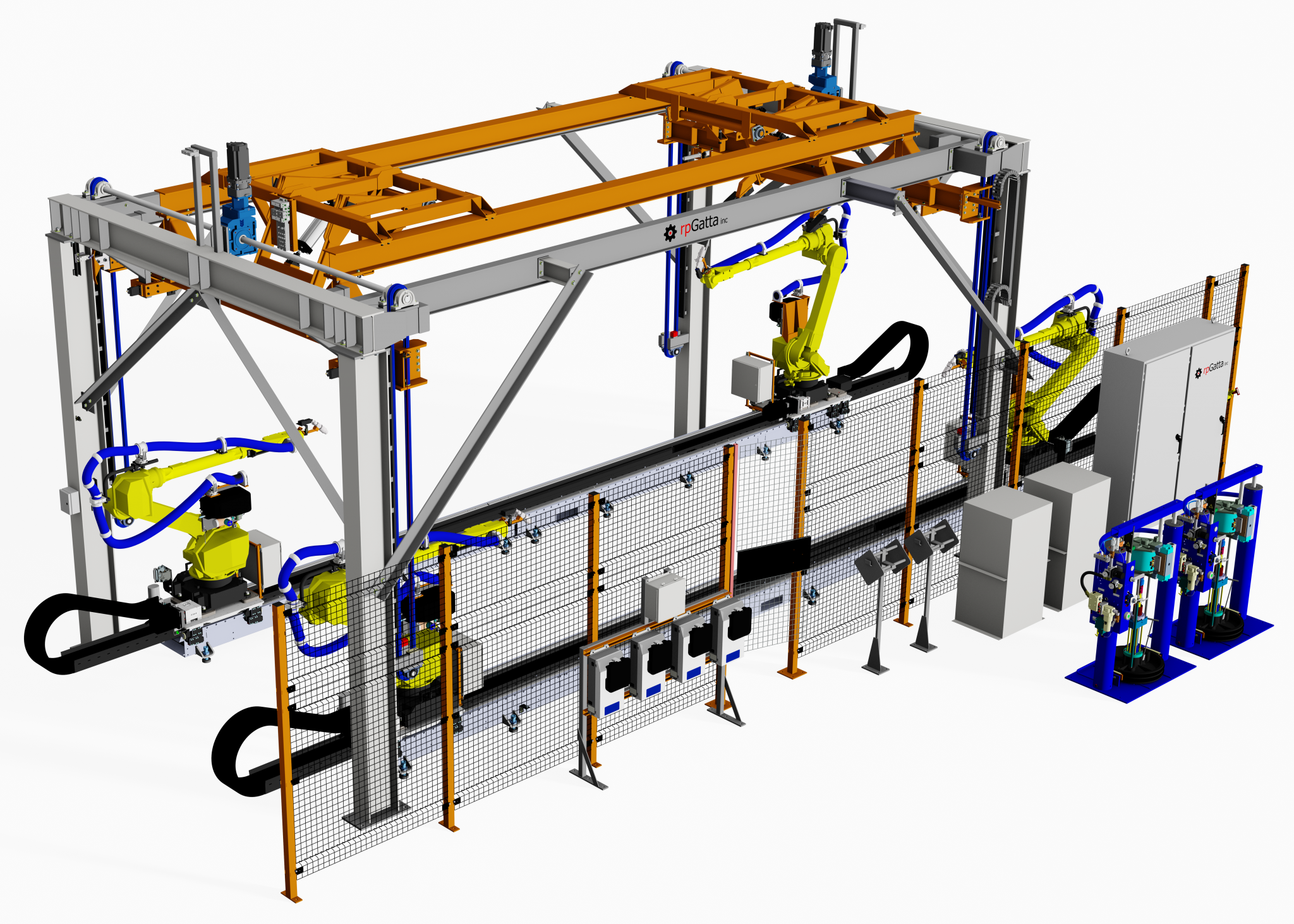

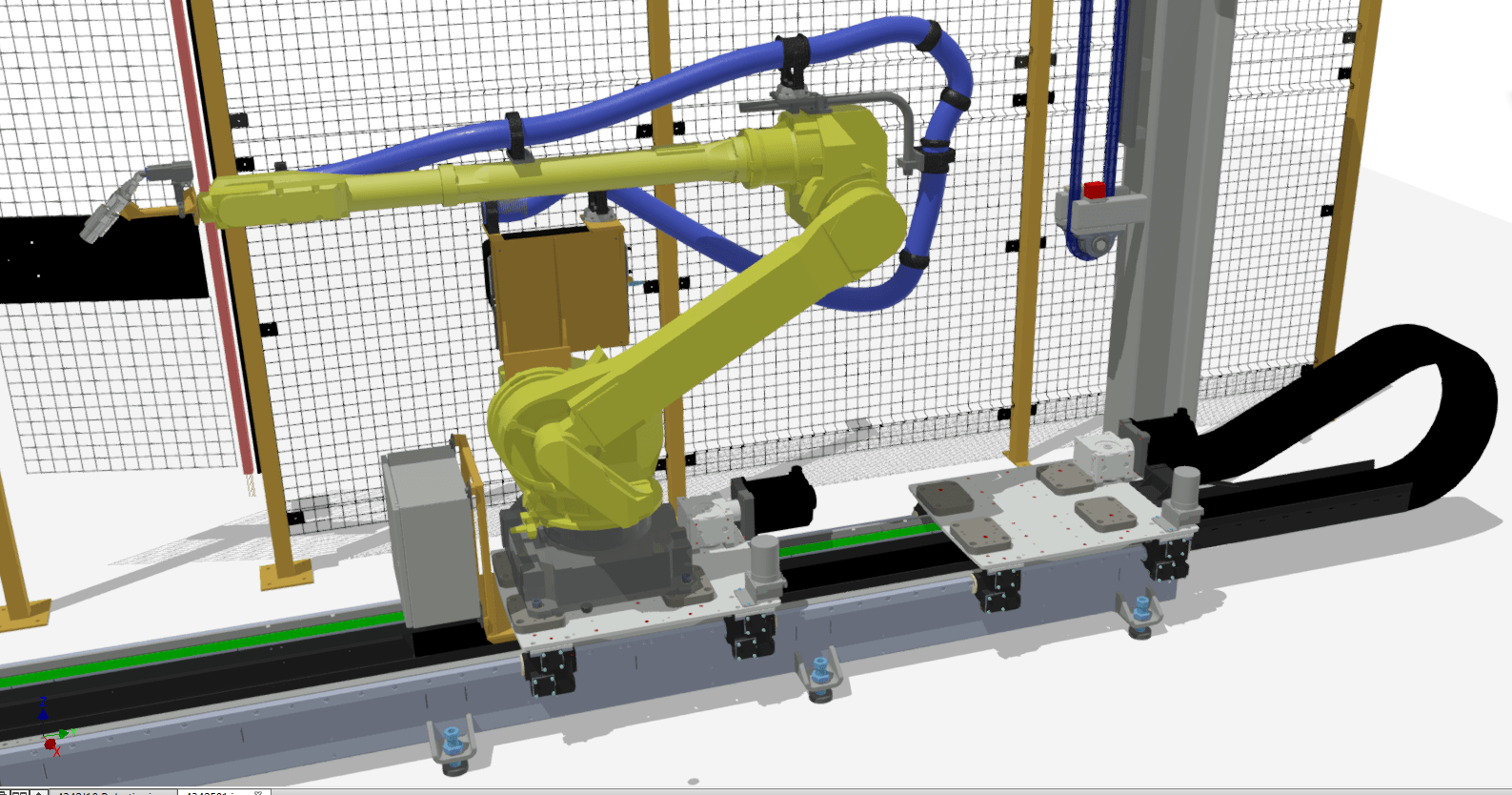

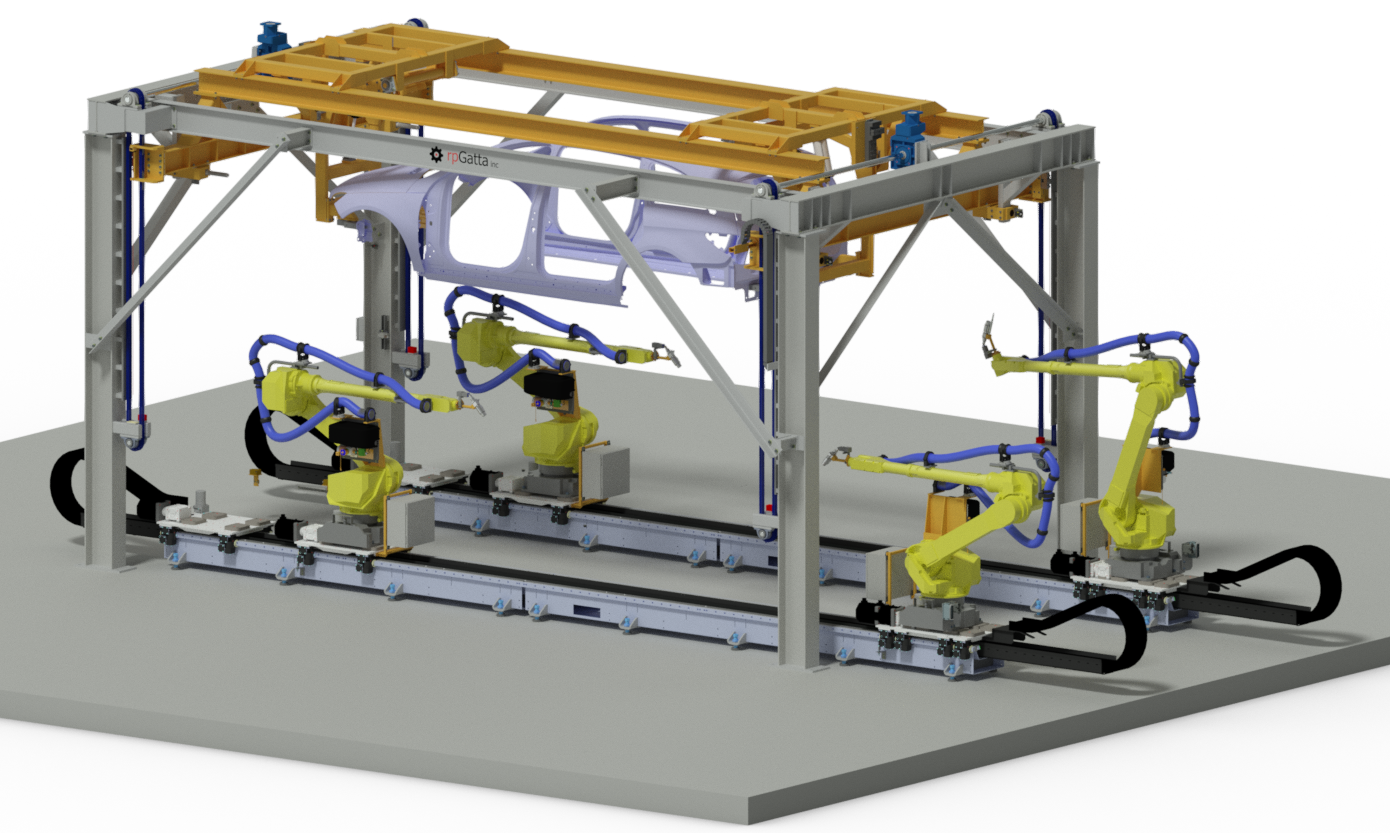

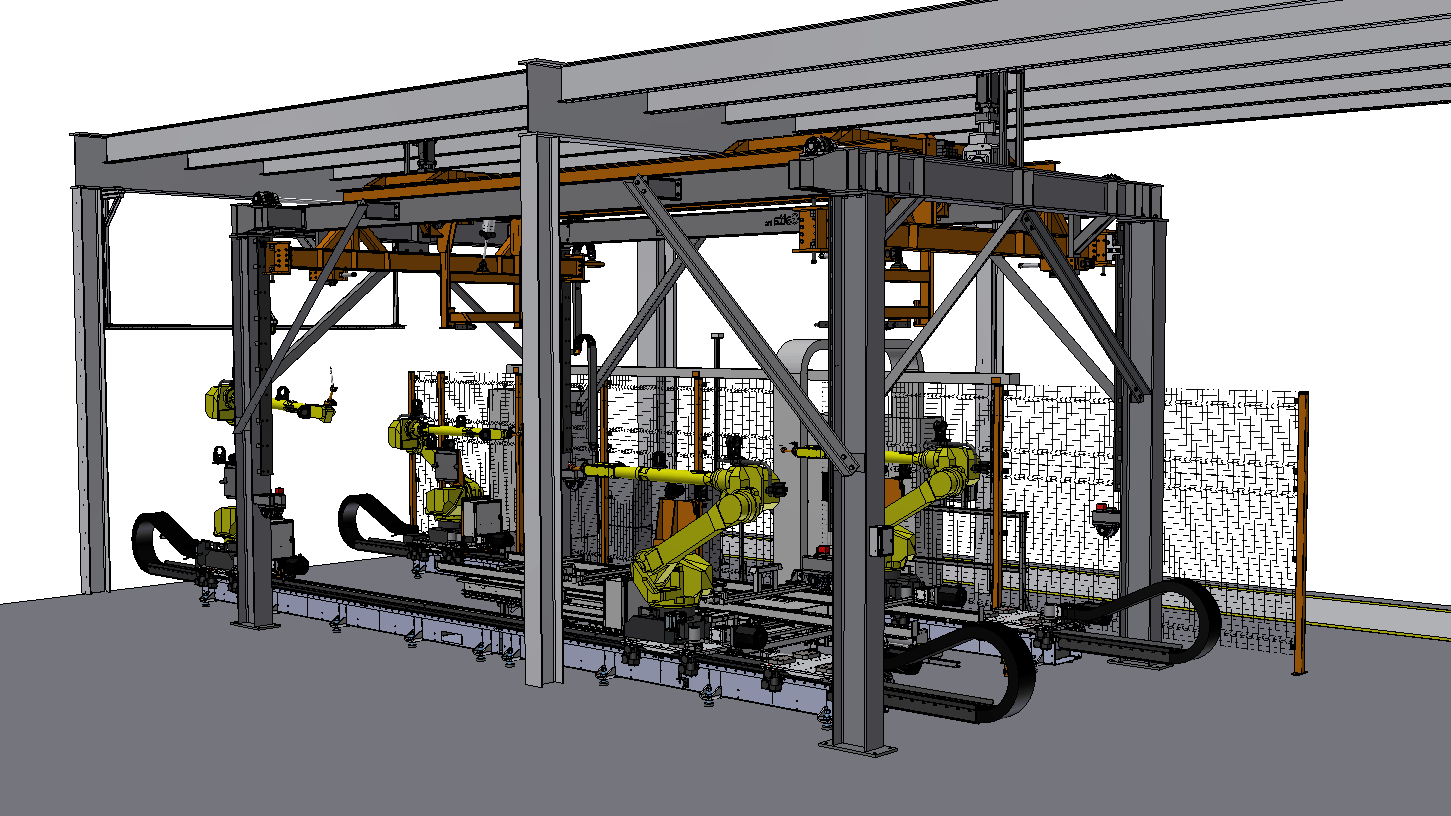

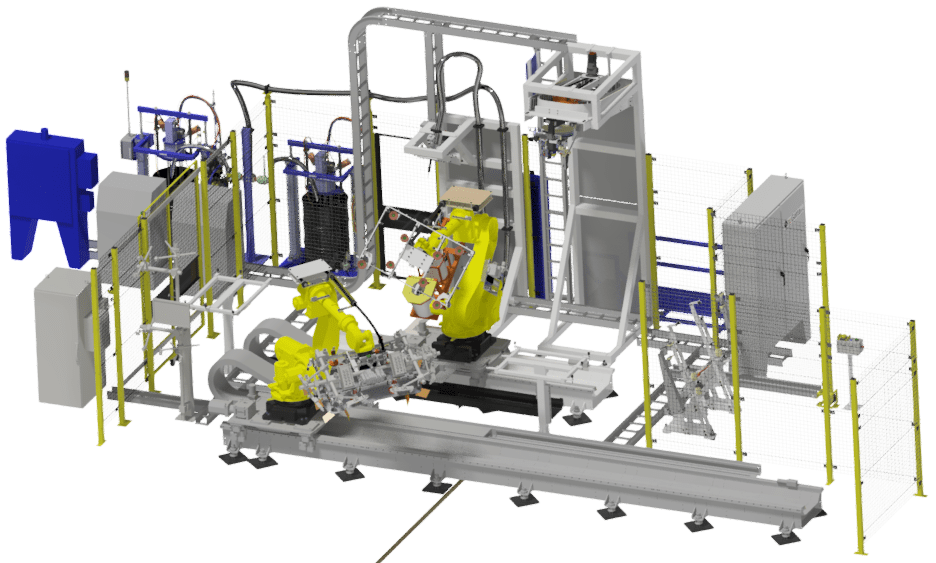

Robotic Sealer Apply Cell

Features:

rpGatta’s robotic sealer apply cell included the custom design and integration of:

- Body Vehicle Lift and Locate Gantry

- Four 6-Axis Robots with Dispensing Attachments

- Two Floor-Mounted 7th Axis Linear Tracks with Dual-Independent Carriages

- Dispensing Equipment

- Control System

- Safety Guarding

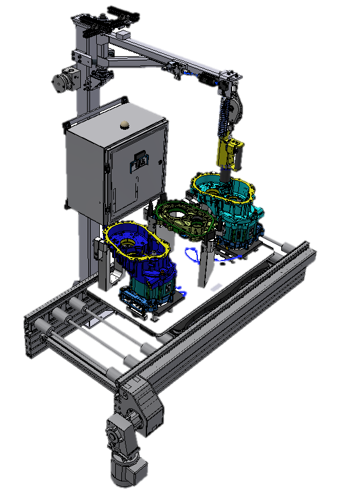

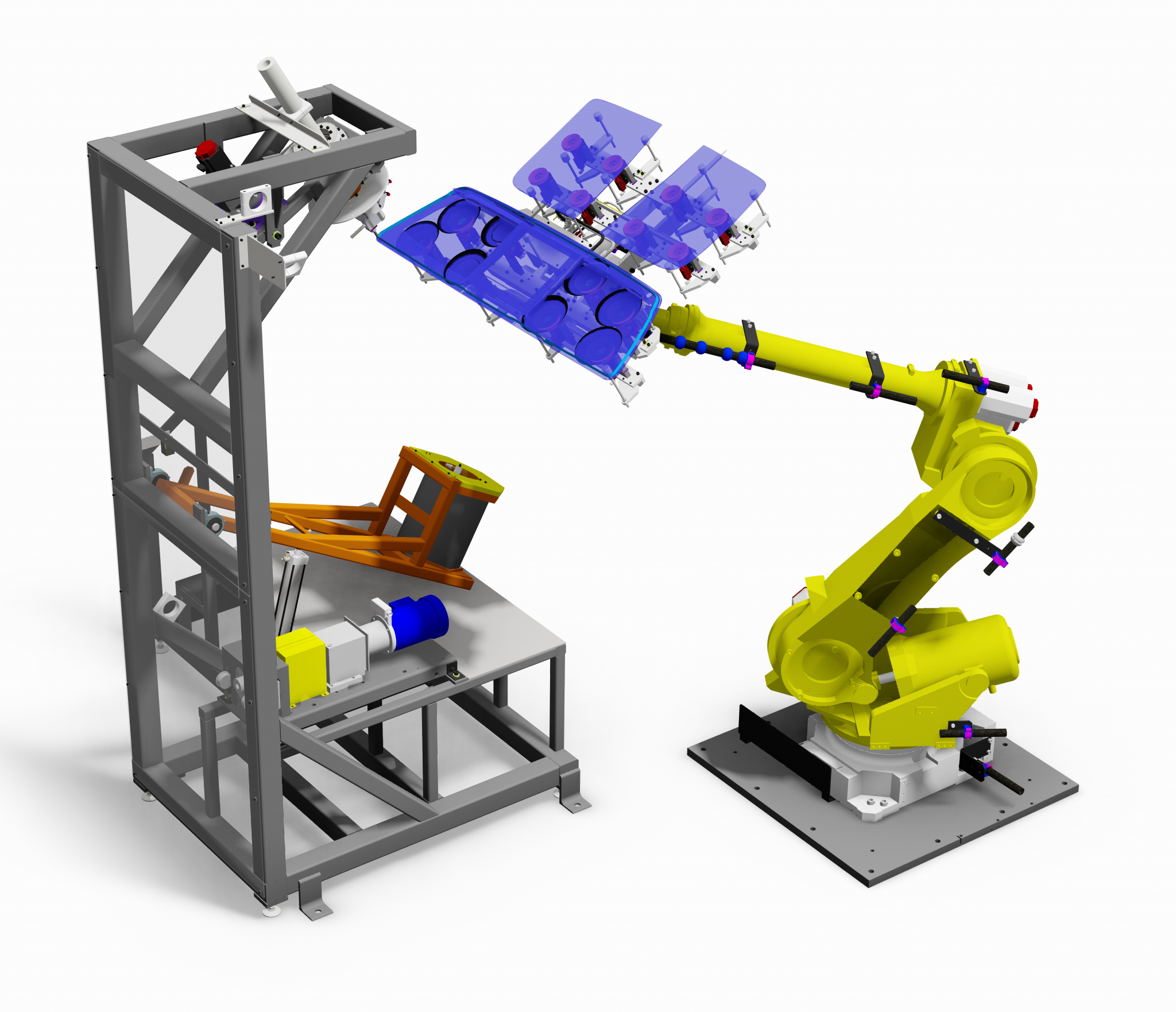

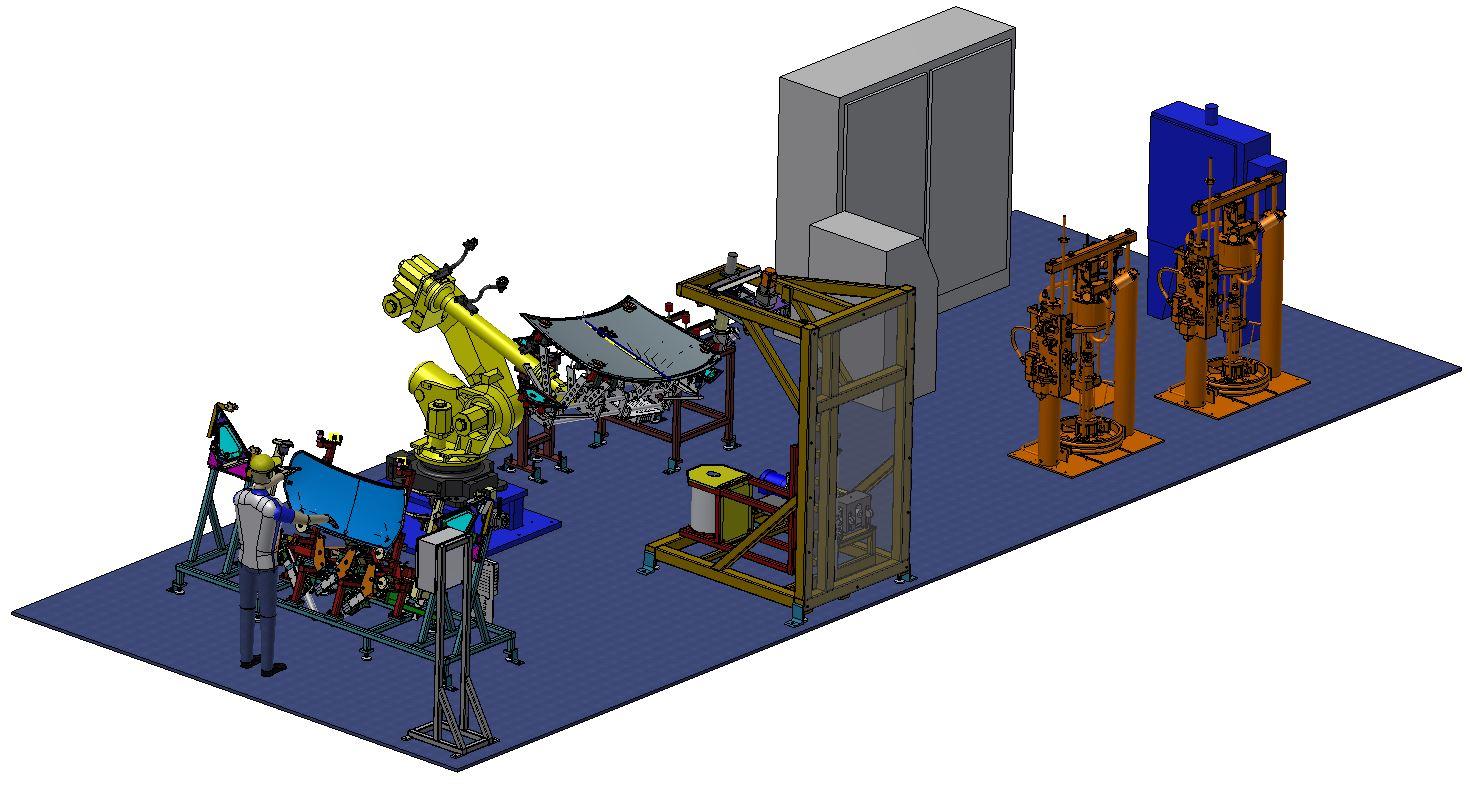

Urethane and Primer Apply Cells

Features:

rpGatta has designed and built numerous robotic urethane apply cells, which include the custom design and integration of:

- Glass load station table capable of housing and auto-centering 3 pieces of glass at a time for up to 3 different models each.

- 6-Axis robot with multiple vacuum cups on the end effector to be able to transport up to 3 pieces of glass at a time

- It is capable of picking the glass, moving the glass around the urethane dispensing nozzle, and placing on an unload station table

- As the robot manipulates the glass components around and beneath the nozzle, the 7th axis servo controlling the nozzle rotates accordingly to ensure the bead profile is consistent around the perimeter

- The urethane dispensing stand has an automatic purging function after a set number of cycles

- The robot places the finished glass onto the glass unload station table where it pneumatically actuates to pivot forward for operators to easily access the glass for a manual installation to the vehicle

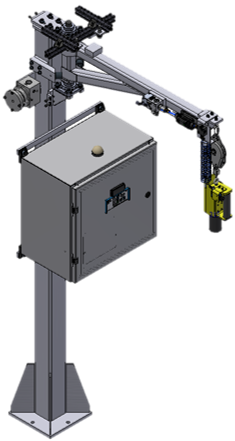

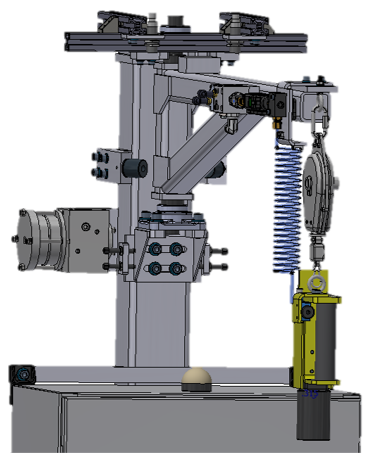

Loctite Dispensing Robot

Grease Dispensing Robot

Grease Dispensing Manual Arm