Lift Systems

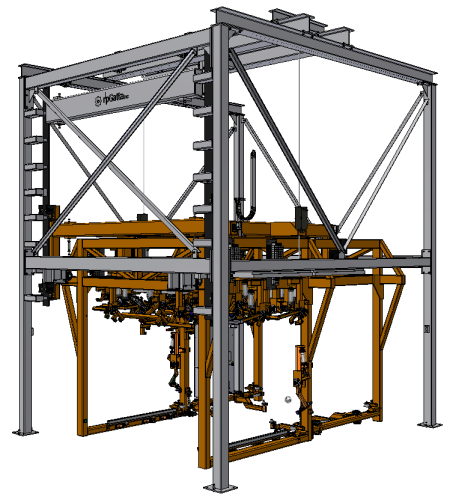

sleeper framer lift

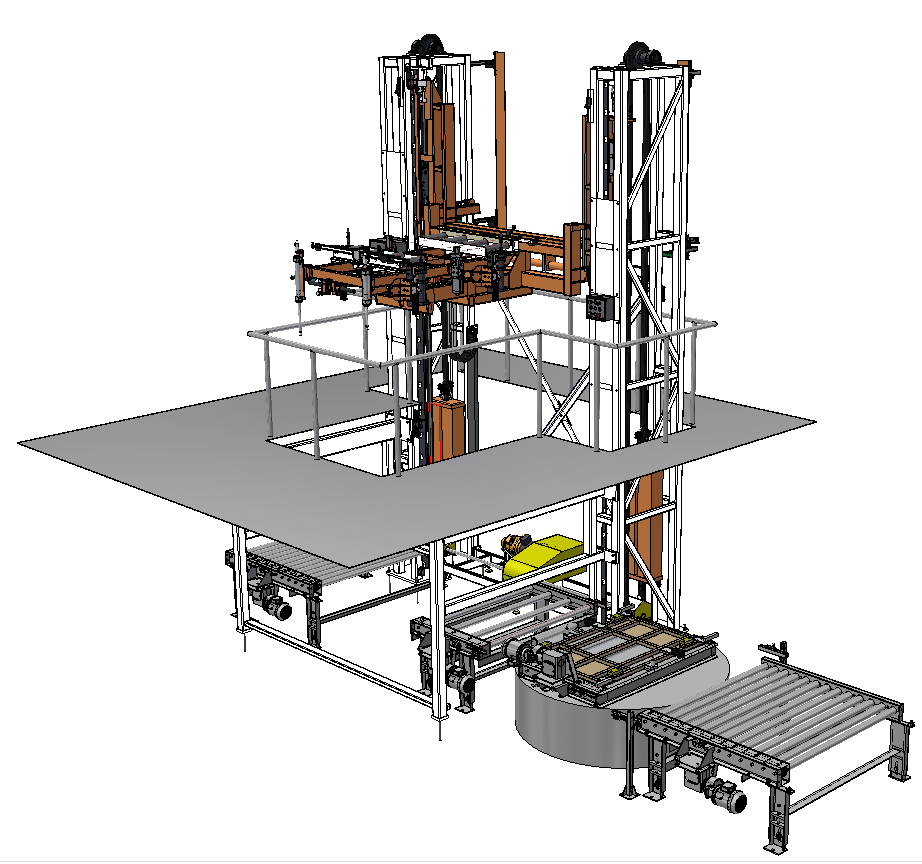

EV Battery Marriage and Auto Secure

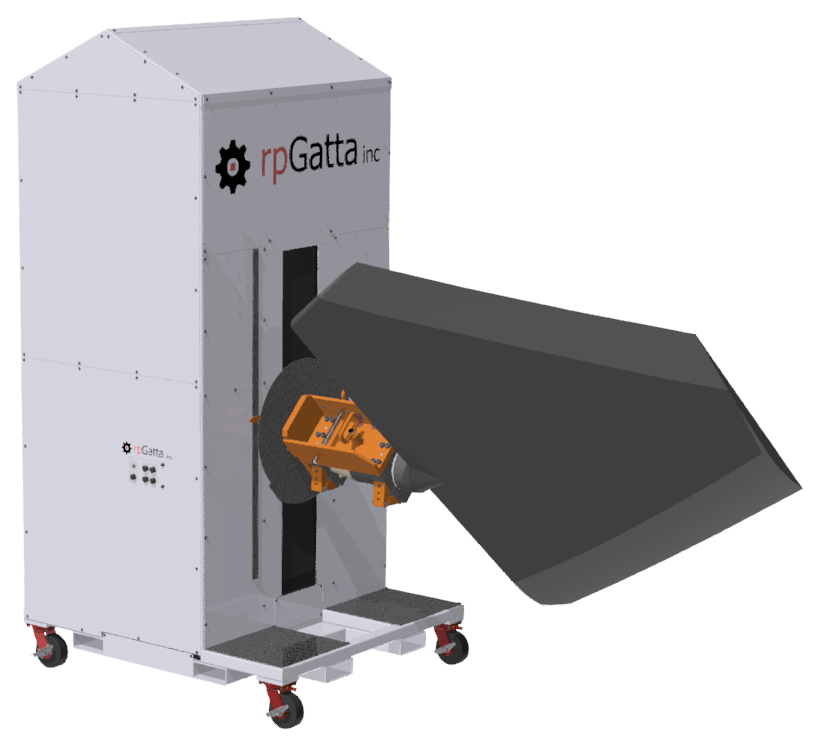

aircraft engine lift

Consists of:

- Lift support structure

- Inner lift frame

- Pneumatically actuated locating fixturing

- Pneumatic clamping system

- Electric hoist

- Safety and operation controls

Features:

- Front Floor Support Arms are pneumatically actuated into and out of build position in order to make room for the Floor to roll through the Framer on the dolly

- Fixture Locating Arms extend from inside the Sleeper as opposed from the outside, this allows for better access loading the Sub-Assemblies from the periphery of the fixture

Features:

- rpGatta's custom designed electric vehicle battery installation system is capable of semi-automatically lifting and fastening the heaviest modern batteries:

- System automatically conveys battery on a pallet into in lifting fixture and centers the battery

- An operator places bolts into the electric torque tools

- The heavy duty electric motor driven lift raises the battery to the under side of the vehicle and locates the battery and fasteners automatically

- Torque specifications are verified and sent to quality database on plant network

- Our decades of automated fastening experience yields robust and highly reliable fastening systems

- PLC Controls, HMI, and Safety Programmable Laser Scanners ensure maximum safety and equipment uptime

Features:

- rpGatta designed and built a horizontal lift assembly workstation for inspection and maintenance on the General Electric/Rolls-Royce F136 JSF Engine

horizontal stabilizer lifts

antenna testing lift

Banked Cylinder Head Manipulator

Features:

- rpGatta designed and built (8) portable fixtures

- Each fixture clamps the shaft of an aircraft horizontal stabilizer

- The operator presses buttons to lift and rotate the stabilizer to assist in the manual paint stripping and applying processes

- These fixtures are explosion-proof and rated for a Class II Division I environment

- The systems utilize pneumatic spring applied caliper disk brakes that disengage when the buttons are held and automatically brake when the buttons are released

- There are pneumatic limit switches strategically positioned such that when the moving clamp mechanism contacts them the brakes will instantly engage to prevent the stabilizer from ever contacting the ground

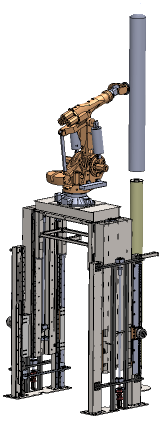

Features:

- rpGatta integrated a robotic lift for the testing of antennas

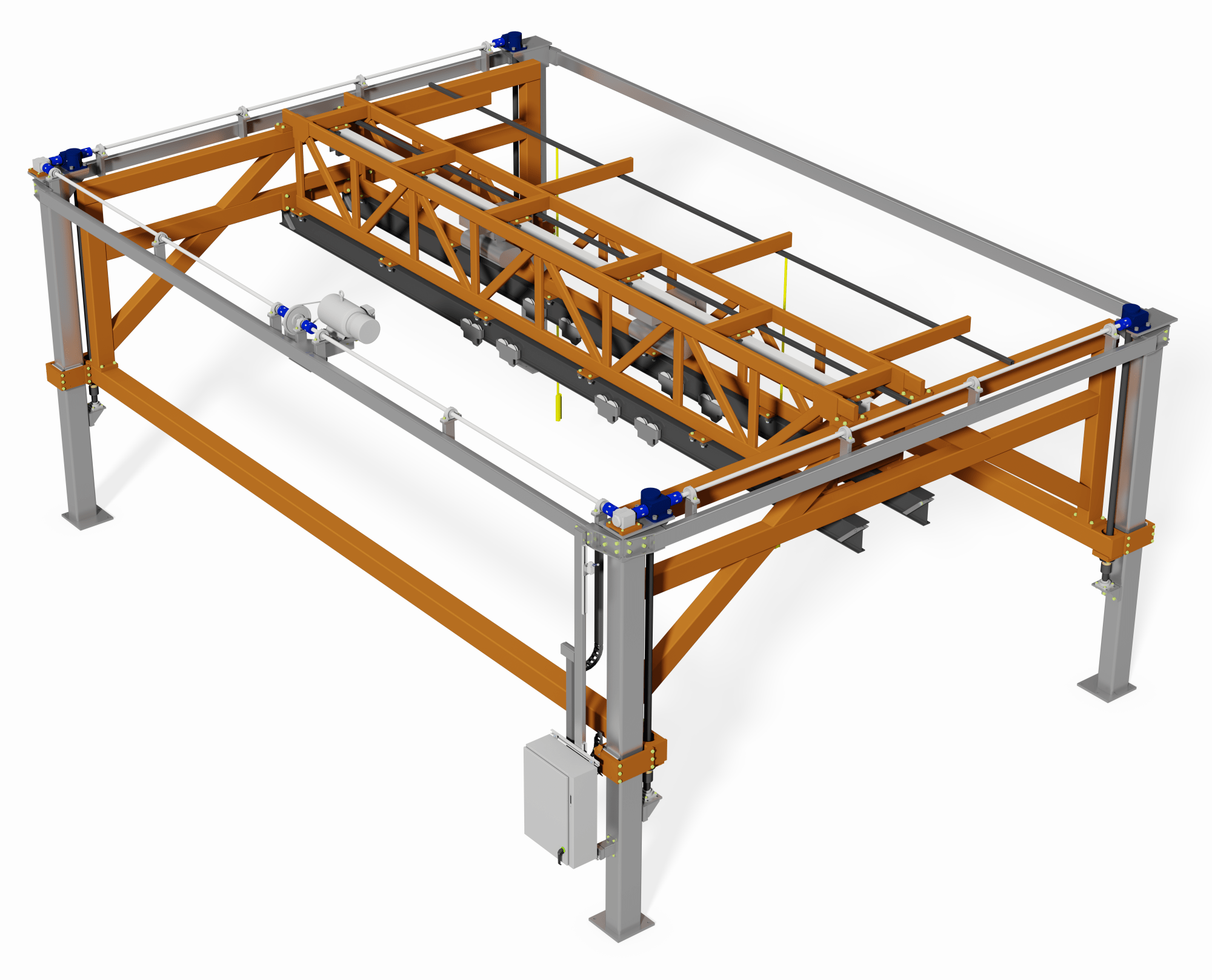

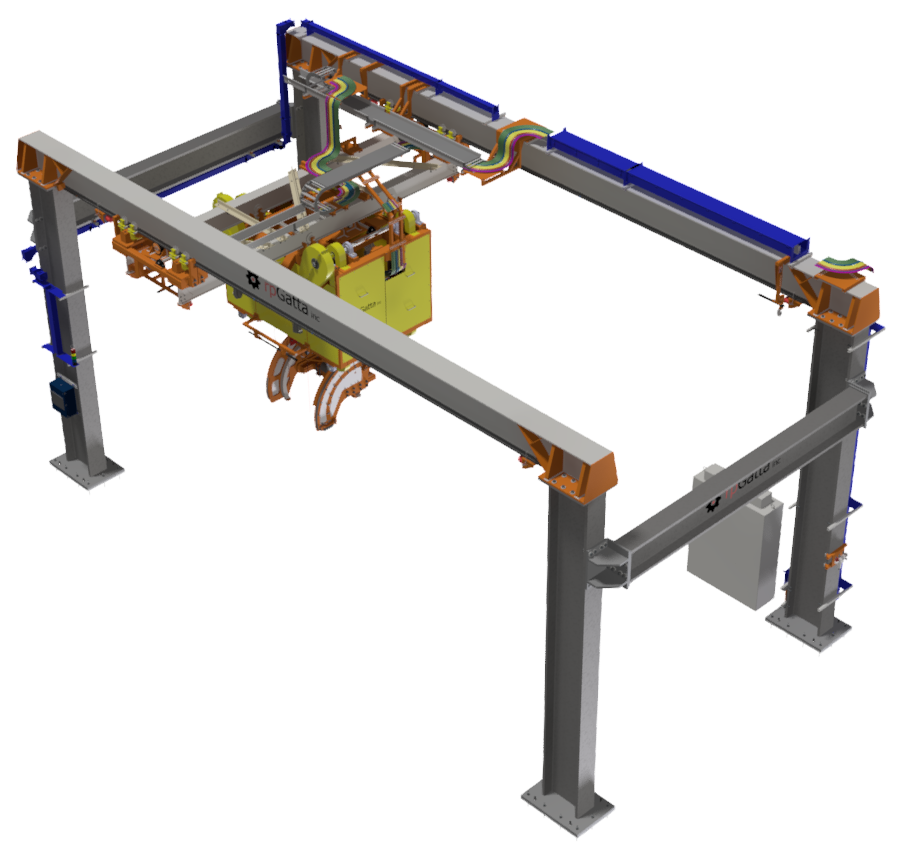

Features:

- rpGatta designed a custom 5 axis servo gantry including a specialized tilt axis for manipulating high payload cylinder head assemblies

- Accepts a variety of engine head sizes and shapes

- Custom End Effector that supports full tilt for inspection and manipulation along with custom grippers for providing a safe grip without interfering with the various assemblies and models

- Ability to disengage servomotors from rail to allow operator to manually guide the gantry

- Laser and sensor assisted pick/place with safeguards to prevent the operator from performing partial or unsecure lifts

- Belly box controls with semi-automatic movement